Hot water treatment effectively eliminates pests by immersing produce in controlled temperature water, ensuring uniform heat penetration without damaging the fruit. Vapour heat treatment uses hot steam to raise the surface temperature, offering a dry alternative that reduces the risk of waterborne diseases and maintains product quality. Both methods are crucial in post-harvest technology for pest disinfestation, with choice depending on crop sensitivity and desired processing conditions.

Table of Comparison

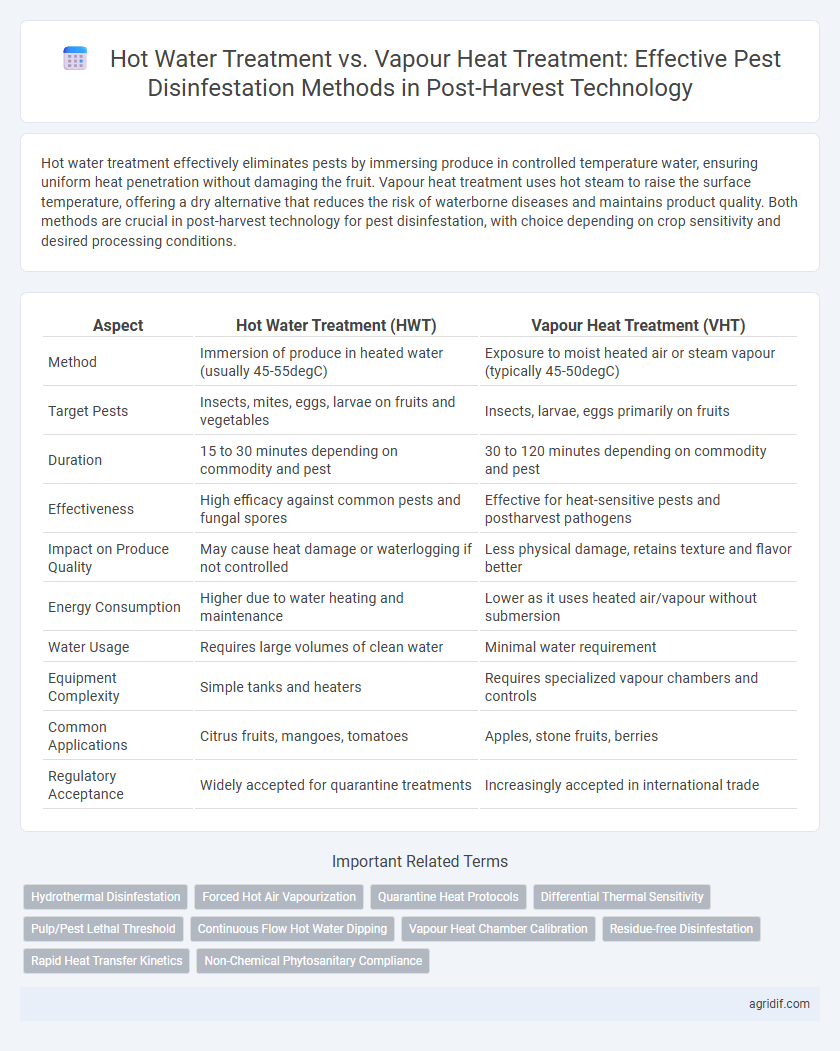

| Aspect | Hot Water Treatment (HWT) | Vapour Heat Treatment (VHT) |

|---|---|---|

| Method | Immersion of produce in heated water (usually 45-55degC) | Exposure to moist heated air or steam vapour (typically 45-50degC) |

| Target Pests | Insects, mites, eggs, larvae on fruits and vegetables | Insects, larvae, eggs primarily on fruits |

| Duration | 15 to 30 minutes depending on commodity and pest | 30 to 120 minutes depending on commodity and pest |

| Effectiveness | High efficacy against common pests and fungal spores | Effective for heat-sensitive pests and postharvest pathogens |

| Impact on Produce Quality | May cause heat damage or waterlogging if not controlled | Less physical damage, retains texture and flavor better |

| Energy Consumption | Higher due to water heating and maintenance | Lower as it uses heated air/vapour without submersion |

| Water Usage | Requires large volumes of clean water | Minimal water requirement |

| Equipment Complexity | Simple tanks and heaters | Requires specialized vapour chambers and controls |

| Common Applications | Citrus fruits, mangoes, tomatoes | Apples, stone fruits, berries |

| Regulatory Acceptance | Widely accepted for quarantine treatments | Increasingly accepted in international trade |

Introduction to Post-Harvest Disinfestation Methods

Hot water treatment and vapour heat treatment are critical post-harvest disinfestation methods used to eliminate pests without chemical residues, enhancing produce safety and shelf life. Hot water treatment involves immersing fruits or vegetables in carefully regulated hot water to eradicate insects and pathogens, while vapour heat treatment exposes produce to controlled moist heat, ensuring deep internal penetration to target pests effectively. Both methods prioritize maintaining product quality and complying with quarantine regulations, making them essential in modern post-harvest technology.

Understanding Hot Water Treatment: Principles and Process

Hot water treatment for pest disinfestation in post-harvest technology involves immersing fruits or vegetables in precisely controlled temperatures, typically between 45-55degC, for specific durations to effectively eliminate pests without compromising product quality. The principle relies on thermal death time, where heat penetrates the produce to disrupt pest metabolism and reproduction while preserving texture and flavor. This process requires careful monitoring of water temperature, exposure time, and cooling methods to avoid heat damage and ensure phytosanitary compliance.

Vapour Heat Treatment: Mechanism and Application

Vapour Heat Treatment (VHT) utilizes saturated steam to raise the temperature of horticultural commodities uniformly, effectively targeting and eliminating insect pests without chemical residues. This method disrupts pest metabolic processes through prolonged exposure to moist heat at controlled temperatures around 46-50degC, ensuring quarantine compliance and preserving fruit quality. VHT is widely applied in quarantine treatments for fruits like mangoes and avocados, offering an eco-friendly alternative to methyl bromide fumigation in post-harvest pest disinfestation.

Efficacy Comparison: Hot Water vs Vapour Heat for Pest Control

Hot water treatment offers rapid and uniform temperature exposure, effectively targeting a wide range of pests in fruits and vegetables, with efficacy dependent on precise temperature and duration control. Vapour heat treatment penetrates the commodity more gently, reducing the risk of heat damage while maintaining high mortality rates for internal and surface pests, particularly in delicate horticultural products. Studies indicate that vapour heat may provide superior pest control efficacy in heat-sensitive crops, whereas hot water treatment remains advantageous for commodities tolerant to short, high-temperature exposures.

Impact on Produce Quality: Texture, Flavor, and Nutrition

Hot water treatment and vapour heat treatment both effectively control pests in post-harvest produce but differ in their impact on texture, flavor, and nutrition. Hot water treatment may cause slight softening and potential nutrient leaching due to direct water contact, potentially affecting firmness and vitamin retention. Vapour heat treatment, being less invasive, generally preserves texture and flavor better by minimizing moisture absorption, thus maintaining higher nutrient levels and overall produce quality.

Operational Requirements and Cost-effectiveness

Hot Water Treatment requires precise temperature control and extended immersion times, demanding sturdy, corrosion-resistant tanks and high energy input, which increases operational costs. Vapour Heat Treatment operates at lower temperatures with shorter exposure periods, utilizing insulated chambers and steam generators that reduce energy consumption and enhance throughput efficiency. While Hot Water Treatment offers thorough pest eradication, Vapour Heat Treatment provides better cost-effectiveness through lower utility expenses and simplified equipment maintenance in post-harvest pest disinfestation.

Suitability for Different Crops and Pest Species

Hot water treatment is highly effective for fruits with thick skins such as mangoes and avocados, targeting pests like fruit flies and mites by penetrating their protective layers. Vapour heat treatment suits delicate crops such as berries and leafy greens, using moist heat to eradicate surface and internal pests including thrips and scales without damaging the produce. Both methods require careful temperature and exposure regulation to maximize pest disinfestation while preserving crop quality and shelf life.

Environmental and Safety Considerations

Hot water treatment for pest disinfestation in post-harvest technology involves immersing produce in heated water, posing risks of water contamination and increased energy consumption. Vapour heat treatment uses saturated steam to elevate produce temperature, reducing water usage and minimizing chemical residues, enhancing environmental sustainability. Safety considerations highlight that vapour heat treatment limits operator exposure to heated liquids and potential pathogen transmissions compared to hot water immersion.

Adoption and Commercial Utilization Worldwide

Hot water treatment is widely adopted in countries like Australia, Japan, and the United States due to its effectiveness in controlling pests on fruits such as mangoes and citrus, supported by established protocols and infrastructure. Vapour heat treatment, though less prevalent, gains commercial traction in regions like Israel and South Africa, favored for its ability to penetrate fruit crevices and its reduced water usage. Both methods face varying degrees of adoption influenced by factors such as cost, equipment availability, and regulatory approvals, shaping their commercial utilization globally in post-harvest pest management.

Future Trends in Post-Harvest Disinfestation Technologies

Emerging post-harvest disinfestation technologies prioritize sustainability and efficacy, with hot water treatment offering precise temperature control to target specific pests without chemical residues, while vapour heat treatment shows promise in uniform heat distribution and reduced energy consumption. Innovations integrating sensor technologies and automation are enhancing the precision of both methods, leading to minimized produce quality degradation and higher throughput. Future trends emphasize combining heat treatments with biological controls and advanced monitoring systems to optimize pest mortality rates and ensure compliance with international phytosanitary standards.

Related Important Terms

Hydrothermal Disinfestation

Hydrothermal disinfestation methods such as Hot Water Treatment and Vapour Heat Treatment effectively target post-harvest pests by elevating commodity temperatures to lethal levels without compromising quality. Hot Water Treatment immerses produce in controlled hot water baths, ensuring uniform heat penetration, while Vapour Heat Treatment exposes produce to hot steam, offering rapid heat transfer with reduced water contact, both optimizing pest control in fresh agricultural products.

Forced Hot Air Vapourization

Forced Hot Air Vapourization in post-harvest pest disinfestation uses controlled hot air to vaporize water, creating saturated steam that penetrates produce surfaces more effectively than traditional hot water treatment. This method reduces thermal damage, enhances pest mortality rates, and maintains fruit quality by ensuring uniform heat distribution and minimizing moisture-related issues.

Quarantine Heat Protocols

Hot water treatment and vapour heat treatment are critical quarantine heat protocols in post-harvest technology for effective pest disinfestation, ensuring compliance with international phytosanitary standards. Hot water treatment involves submerging produce in controlled-temperature baths to eradicate pests, while vapour heat treatment uses high-temperature steam to penetrate and eliminate infestations without compromising the quality of heat-sensitive commodities.

Differential Thermal Sensitivity

Hot Water Treatment exploits the vulnerability of pests to direct immersion in regulated temperatures, typically between 45-55degC, effectively eradicating infestations without compromising fruit quality. Vapour Heat Treatment utilizes saturated steam at similar temperature ranges but offers enhanced penetration and uniform heat distribution, targeting pests with higher thermal resistance through precise control of exposure time and humidity levels.

Pulp/Pest Lethal Threshold

Hot water treatment targets pests in harvested fruits by maintaining temperatures between 48-52degC, effectively penetrating the fruit pulp to surpass pest lethal thresholds without damaging quality. Vapour heat treatment relies on saturated steam at 46-50degC, achieving pest mortality through prolonged exposure while minimizing moisture-related pulp damage and preserving the fruit's integrity.

Continuous Flow Hot Water Dipping

Continuous Flow Hot Water Dipping ensures rapid and uniform pest disinfestation by maintaining precise temperature control and exposure time, minimizing quality degradation in fruits and vegetables. This method outperforms Vapour Heat Treatment by enabling higher throughput and better energy efficiency while preventing thermal damage during post-harvest processing.

Vapour Heat Chamber Calibration

Vapour heat treatment relies on precise chamber calibration to maintain uniform temperature and humidity levels critical for effective pest disinfestation in post-harvest technology. Accurate monitoring and control of vapour heat parameters ensure consistent biosecurity standards, reducing crop losses while preserving fruit quality.

Residue-free Disinfestation

Hot water treatment provides effective residue-free disinfestation by immersing fruits in controlled temperature water, eliminating pests without chemical residues, while vapour heat treatment uses moist hot air to achieve pest eradication without leaving harmful residues on produce. Both methods ensure compliance with export standards by maintaining product quality and safety through non-chemical, environmentally friendly pest control.

Rapid Heat Transfer Kinetics

Hot Water Treatment achieves rapid heat transfer through direct immersion, allowing uniform temperature penetration and effective pest disinfestation in post-harvest technology. Vapour Heat Treatment relies on steam contact, which provides efficient heat transfer kinetics but may result in slower temperature equilibration compared to hot water immersion.

Non-Chemical Phytosanitary Compliance

Hot Water Treatment uses controlled immersion in water at temperatures typically between 46-52degC to eradicate pests and pathogens on harvested produce, maintaining fruit quality while ensuring non-chemical phytosanitary compliance. Vapour Heat Treatment applies saturated steam at 46-50degC for short durations, offering an eco-friendly alternative by penetrating complex fruit surfaces for effective disinfestation without chemical residues.

Hot Water Treatment vs Vapour Heat Treatment for pest disinfestation Infographic

agridif.com

agridif.com