Percussion threshing utilizes impact forces to separate seeds from the crop, offering gentle seed handling and minimal damage, which is ideal for delicate seeds. Mechanical threshing employs rotating drums or cylinders that exert continuous friction and force, enhancing throughput but potentially causing higher seed breakage. Selecting between percussion and mechanical threshing depends on the seed type, desired quality, and harvesting scale, balancing efficiency with seed integrity.

Table of Comparison

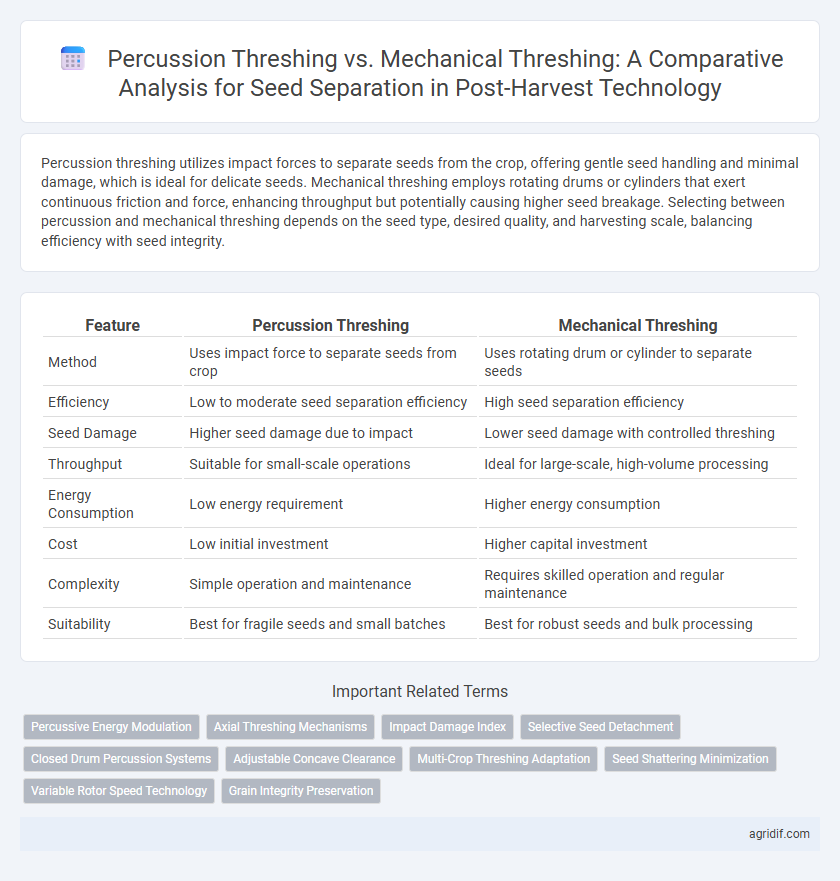

| Feature | Percussion Threshing | Mechanical Threshing |

|---|---|---|

| Method | Uses impact force to separate seeds from crop | Uses rotating drum or cylinder to separate seeds |

| Efficiency | Low to moderate seed separation efficiency | High seed separation efficiency |

| Seed Damage | Higher seed damage due to impact | Lower seed damage with controlled threshing |

| Throughput | Suitable for small-scale operations | Ideal for large-scale, high-volume processing |

| Energy Consumption | Low energy requirement | Higher energy consumption |

| Cost | Low initial investment | Higher capital investment |

| Complexity | Simple operation and maintenance | Requires skilled operation and regular maintenance |

| Suitability | Best for fragile seeds and small batches | Best for robust seeds and bulk processing |

Introduction to Seed Separation Techniques

Percussion threshing uses impact forces to separate seeds from the crop husks, providing effective detachment for crops with delicate grains. Mechanical threshing relies on rotary or tangential action to strip seeds, offering higher throughput but potentially causing grain damage. Seed separation efficiency depends on selecting appropriate threshing parameters tailored to crop type and seed sensitivity.

Overview of Percussion Threshing

Percussion threshing utilizes rapid, repetitive impacts to dislodge seeds from crops, providing efficient separation particularly suited for delicate grain varieties. This method reduces seed damage and maintains higher viability compared to mechanical threshing, which often applies continuous friction and pressure. The controlled impact mechanism in percussion threshing offers improved seed quality retention and is frequently preferred in post-harvest seed processing for maintaining germination rates.

Overview of Mechanical Threshing

Mechanical threshing employs specialized machines to separate seeds from crop stalks efficiently, significantly reducing manual labor and processing time compared to traditional methods. These machines use rotating drums or cylinders with beater bars to apply controlled force, ensuring minimal grain damage and higher throughput. Advances in mechanical threshing technology optimize seed separation by enhancing grain-cleaning capabilities and adjusting to diverse crop types and moisture levels.

Comparative Efficiency of Threshing Methods

Percussion threshing employs direct impact to dislodge seeds, offering higher precision in separating fragile grains with minimal damage, whereas mechanical threshing utilizes continuous mechanical force, resulting in faster processing but increased seed breakage. Efficiency metrics indicate percussion threshing achieves seed separation rates exceeding 90% in delicate crops, while mechanical threshing shows greater throughput but up to 15% seed damage. Optimal method selection depends on crop type, seed sensitivity, and desired balance between speed and seed integrity.

Impact on Seed Quality and Integrity

Percussion threshing uses rapid, localized impact to separate seeds, often preserving seed coat integrity and maintaining higher germination rates due to minimal abrasion. Mechanical threshing involves continuous rubbing and friction, which can cause increased seed coat damage, reducing seed viability and overall quality. Studies demonstrate that percussion threshing results in fewer broken seeds and less contamination, making it preferable for high-quality seed separation in post-harvest processing.

Labor and Cost Considerations

Percussion threshing offers a lower-cost solution with minimal labor requirements ideal for small-scale farmers, utilizing simple equipment that reduces upfront investment. Mechanical threshing demands higher capital for machinery purchase and maintenance but significantly decreases labor intensity and processing time, enabling large-scale operations to optimize efficiency. Evaluating labor availability and budget constraints is crucial in selecting between these methods for effective seed separation during post-harvest processing.

Energy Consumption Analysis

Percussion threshing utilizes impact forces to separate seeds, generally consuming less energy than mechanical threshing, which relies on rotary mechanisms and continuous motion. Mechanical threshing often results in higher energy consumption due to the power needed to operate rotating drums and conveyance systems. Energy efficiency analysis shows percussion threshing is preferable for small-scale operations seeking reduced power costs and lower environmental impact.

Suitability for Different Crop Types

Percussion threshing is highly effective for delicate crops such as pulses and oilseeds, minimizing seed damage while ensuring efficient separation. Mechanical threshing suits robust cereal crops like wheat and maize, offering faster processing and higher throughput. Crop-specific factors such as grain size, seed coat thickness, and moisture content determine the optimal threshing method to maximize seed quality and yield.

Environmental and Sustainability Aspects

Percussion threshing employs repetitive impact to separate seeds, resulting in lower energy consumption and reduced greenhouse gas emissions compared to mechanical threshing, which relies on continuous rotational power and typically demands higher fuel usage. The minimized mechanical damage in percussion threshing prolongs seed viability, supporting sustainable seed storage and reducing waste within agricultural supply chains. Adoption of percussion threshing technology promotes eco-friendly post-harvest processing by conserving resources and enhancing the long-term sustainability of seed production systems.

Future Trends in Threshing Technologies

Future trends in threshing technologies emphasize increased automation and efficiency through smart sensors and AI-driven control systems enhancing both percussion and mechanical threshing methods. Innovations in precision threshing devices aim to minimize seed damage and maximize separation accuracy, leveraging real-time monitoring of crop moisture and kernel condition. Integration of IoT platforms enables data-driven maintenance and optimization, promising sustainable post-harvest processing with reduced labor and energy consumption.

Related Important Terms

Percussive Energy Modulation

Percussion threshing utilizes percussive energy modulation to selectively strike seeds, minimizing damage and improving separation efficiency compared to mechanical threshing, which relies on continuous mechanical force that can increase seed breakage. Optimizing percussive impact frequency and intensity enhances seed recovery rates and preserves seed viability in post-harvest processing.

Axial Threshing Mechanisms

Axial threshing mechanisms in percussion threshing utilize high-frequency impacts to gently separate seeds, minimizing grain breakage and preserving seed viability, making them ideal for delicate crops. Mechanical threshing with axial rotors employs continuous friction and centrifugal force, increasing throughput but potentially causing higher seed damage and reduced quality in comparison.

Impact Damage Index

Percussion threshing demonstrates a lower Impact Damage Index compared to mechanical threshing, preserving higher seed viability and reducing kernel breakage during seed separation. In contrast, mechanical threshing often results in increased physical damage due to continuous friction and pressure, adversely affecting seed quality and germination rates.

Selective Seed Detachment

Percussion threshing offers selective seed detachment by using controlled impact forces that minimize seed damage and preserve seed viability, essential for high-quality seed separation. Mechanical threshing, while efficient for bulk processing, often causes higher seed breakage due to generalized force application, reducing the effectiveness of selective seed detachment in post-harvest technology.

Closed Drum Percussion Systems

Closed drum percussion systems in post-harvest technology enhance seed separation efficiency by minimizing grain damage and reducing material loss compared to open mechanical threshers. The enclosed design allows precise control over impact force, ensuring higher kernel integrity and improved throughput during threshing operations.

Adjustable Concave Clearance

Adjustable concave clearance in percussion threshing enables precise control over seed separation by minimizing grain damage and optimizing threshing efficiency, especially for varying crop types and moisture levels. Mechanical threshing, while faster, often lacks such fine-tuned adjustment, leading to higher grain breakage and reduced seed quality.

Multi-Crop Threshing Adaptation

Percussion threshing offers efficient seed separation with minimal grain damage across multiple crop types, making it highly adaptable for diverse post-harvest operations. Mechanical threshing systems, while faster and suitable for large volumes, often require crop-specific adjustments, limiting their flexibility in multi-crop threshing applications.

Seed Shattering Minimization

Percussion threshing employs rapid impact forces that gently detach seeds with minimal damage, significantly reducing seed shattering compared to mechanical threshing methods that apply continuous rubbing and pressure. Optimizing percussion threshing parameters such as drum speed and concave clearance effectively minimizes seed loss and enhances seed quality during post-harvest processing.

Variable Rotor Speed Technology

Variable Rotor Speed Technology in percussion threshing enhances seed separation efficiency by adjusting the rotor speed to match crop type and moisture content, reducing seed damage and increasing throughput. Mechanical threshing benefits less from variable speeds as it primarily relies on consistent, high-speed settings that optimize grain separation but may cause more kernel breakage.

Grain Integrity Preservation

Percussion threshing utilizes gentle, oscillatory impacts that minimize kernel damage, thereby preserving grain integrity more effectively than mechanical threshing methods, which often apply higher mechanical forces leading to increased grain breakage and moisture loss. Maintaining seed viability and quality through percussion threshing enhances post-harvest value and supports efficient storage and germination rates.

Percussion Threshing vs Mechanical Threshing for Seed Separation Infographic

agridif.com

agridif.com