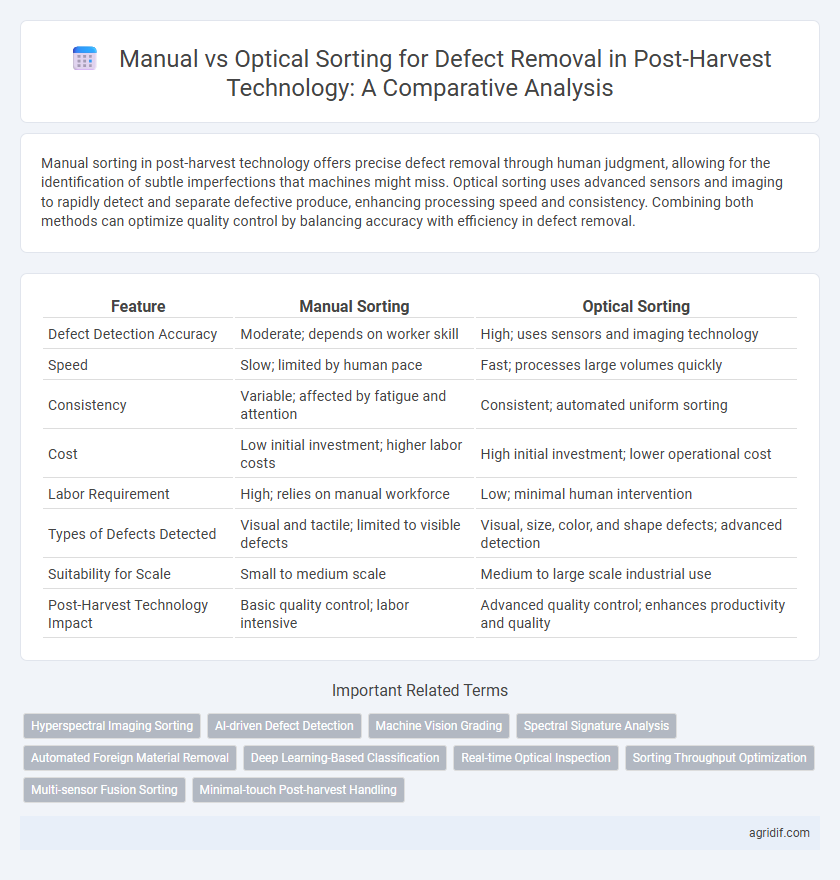

Manual sorting in post-harvest technology offers precise defect removal through human judgment, allowing for the identification of subtle imperfections that machines might miss. Optical sorting uses advanced sensors and imaging to rapidly detect and separate defective produce, enhancing processing speed and consistency. Combining both methods can optimize quality control by balancing accuracy with efficiency in defect removal.

Table of Comparison

| Feature | Manual Sorting | Optical Sorting |

|---|---|---|

| Defect Detection Accuracy | Moderate; depends on worker skill | High; uses sensors and imaging technology |

| Speed | Slow; limited by human pace | Fast; processes large volumes quickly |

| Consistency | Variable; affected by fatigue and attention | Consistent; automated uniform sorting |

| Cost | Low initial investment; higher labor costs | High initial investment; lower operational cost |

| Labor Requirement | High; relies on manual workforce | Low; minimal human intervention |

| Types of Defects Detected | Visual and tactile; limited to visible defects | Visual, size, color, and shape defects; advanced detection |

| Suitability for Scale | Small to medium scale | Medium to large scale industrial use |

| Post-Harvest Technology Impact | Basic quality control; labor intensive | Advanced quality control; enhances productivity and quality |

Overview of Defect Removal in Post-Harvest Agricultural Processing

Manual sorting in post-harvest agricultural processing relies on human judgment to identify and remove defective produce, ensuring quality control through tactile and visual assessment. Optical sorting uses advanced imaging technologies and machine learning algorithms to detect defects such as discoloration, size irregularities, and surface damage with higher speed and consistency. Combining manual and optical sorting optimizes defect removal efficiency, reduces labor costs, and maintains product quality standards across large-scale processing operations.

Manual Sorting: Traditional Practices and Methods

Manual sorting in post-harvest technology relies on skilled workers to visually inspect and separate defective produce based on size, color, and texture. This traditional method allows for the detection of subtle defects such as bruises, rot, or insect damage that machine-based systems may overlook. Despite being labor-intensive, manual sorting ensures high accuracy in defect removal for delicate fruits and vegetables where automated optical sorting may not be as effective.

Optical Sorting Technologies: An Introduction

Optical sorting technologies utilize advanced sensors and machine learning algorithms to identify and remove defective produce with high precision and speed. These systems analyze color, shape, size, and surface defects, significantly enhancing sorting accuracy and throughput compared to manual methods. Implementation of optical sorting leads to reduced labor costs, consistent product quality, and minimized waste in post-harvest processes.

Efficiency Comparison: Manual vs Optical Sorting

Manual sorting relies on human labor to identify and remove defective produce, resulting in variable efficiency influenced by worker skill and fatigue. Optical sorting employs advanced sensor technology, such as hyperspectral imaging and machine learning algorithms, to detect defects with higher accuracy and speed, reducing labor costs and increasing throughput. Optical systems achieve sorting speeds of up to thousands of units per minute, significantly outperforming manual methods typically limited to several hundred units per hour.

Accuracy in Defect Detection: Human Hands vs Machine Vision

Manual sorting relies on human sensory perception, enabling workers to detect subtle defects through tactile and visual cues, though it is subject to fatigue and inconsistency. Optical sorting systems leverage advanced machine vision algorithms and high-resolution cameras, achieving higher precision in identifying defects based on color, shape, and texture, thus reducing error rates. Studies indicate that optical sorting can consistently detect up to 95% of surface defects, surpassing average human accuracy, which ranges between 70-85%.

Cost Implications: Labor vs Technological Investment

Manual sorting for defect removal in post-harvest technology involves significant labor costs due to the need for skilled workers to inspect and separate produce individually, which can limit scalability and efficiency. Optical sorting systems require a higher initial technological investment, including equipment purchase and maintenance, but offer faster processing speeds and consistent defect detection, reducing long-term labor expenses. The decision between manual and optical sorting depends on production scale, budget constraints, and desired throughput, with optical sorting becoming more cost-effective in large-scale operations.

Impact on Product Quality and Consistency

Manual sorting allows for the identification of subtle defects based on human sensory evaluation, enhancing product quality through nuanced selection. Optical sorting employs advanced sensors and machine learning algorithms to consistently detect and remove defects such as discoloration, size irregularities, and foreign materials at high speed. The integration of optical sorting significantly improves product consistency and throughput while minimizing human error and labor costs.

Scalability and Throughput: Meeting Market Demands

Manual sorting offers limited scalability and throughput due to its labor-intensive nature and slower processing speed, restricting the volume of produce handled daily. Optical sorting leverages advanced sensors and machine learning algorithms to rapidly and accurately identify defects, enabling higher throughput and consistent quality suitable for large-scale operations. This technological advantage allows optical sorting systems to meet increasing market demands efficiently, surpassing the capacity constraints inherent in manual sorting methods.

Sustainability and Waste Reduction Outcomes

Manual sorting in post-harvest technology relies on human inspection to identify and remove defective produce, often resulting in higher labor costs and inconsistent defect detection, which can lead to increased food waste. Optical sorting utilizes advanced imaging and sensor technology to accurately detect defects, improving throughput and enabling precise removal of substandard items, thereby significantly reducing waste and promoting sustainability. The integration of optical sorting enhances resource efficiency, minimizes environmental impact by decreasing spoilage, and supports sustainable supply chains through better quality control and reduced food loss.

Future Trends in Post-Harvest Sorting Technologies

Future trends in post-harvest sorting technologies emphasize a shift from manual sorting toward advanced optical sorting systems equipped with hyperspectral imaging and AI-driven defect detection. These cutting-edge optical sorters enhance accuracy, speed, and consistency, significantly reducing human error and labor costs while improving product quality and shelf life. Integration of machine learning algorithms allows real-time adaptation to varying defect types, setting new standards in efficiency and sustainability within the post-harvest supply chain.

Related Important Terms

Hyperspectral Imaging Sorting

Hyperspectral imaging sorting in post-harvest technology enhances defect removal by capturing detailed spectral information across multiple wavelengths, enabling precise identification of internal and external product defects that manual sorting often misses. This technology increases sorting accuracy, reduces labor costs, and improves overall product quality by allowing real-time, non-destructive analysis compared to traditional manual methods.

AI-driven Defect Detection

AI-driven optical sorting technology significantly enhances defect removal efficiency by using advanced machine learning algorithms and high-resolution imaging to identify and segregate substandard produce quickly, surpassing the accuracy and speed of traditional manual sorting. This automated system reduces human error, increases throughput, and ensures consistent quality control in post-harvest processing operations.

Machine Vision Grading

Machine vision grading in post-harvest technology offers superior accuracy and consistency over manual sorting by using high-resolution cameras and advanced algorithms to detect and classify defects in produce. Optical sorting systems increase throughput and reduce labor costs while minimizing human error, ensuring higher quality standards and enhanced marketability of the harvested products.

Spectral Signature Analysis

Manual sorting in post-harvest technology relies on human sensory evaluation, which often lacks consistency and efficiency in defect removal, while optical sorting utilizes spectral signature analysis to accurately detect and classify defects based on specific wavelength reflectance patterns. Spectral signature analysis enhances defect removal by enabling high-speed, non-destructive inspection that differentiates subtle surface and subsurface anomalies invisible to the human eye, improving overall product quality and reducing post-harvest losses.

Automated Foreign Material Removal

Manual sorting relies on human inspection to identify and remove defective produce but is limited by speed, consistency, and subjectivity. Optical sorting systems use advanced imaging technology and sensors to rapidly detect and automatically eliminate foreign materials and defects, enhancing accuracy and throughput in post-harvest processing.

Deep Learning-Based Classification

Deep learning-based classification enhances optical sorting by accurately identifying and removing defective produce through advanced image analysis, surpassing the precision and speed limitations of manual sorting. This technology leverages convolutional neural networks to analyze subtle visual defects, ensuring higher quality control in post-harvest processing.

Real-time Optical Inspection

Real-time optical inspection in post-harvest technology significantly enhances defect removal efficiency by using advanced cameras and sensors to detect size, color, and surface defects on fruits and vegetables. Compared to manual sorting, optical sorting reduces human error, increases throughput, and enables precise quality control by rapidly processing large volumes with consistent accuracy.

Sorting Throughput Optimization

Manual sorting relies on human labor to identify and remove defects but is limited by slower throughput and higher variability in accuracy, impacting overall processing efficiency. Optical sorting uses advanced sensors and machine learning algorithms to rapidly detect and eliminate defective produce, significantly increasing sorting throughput while maintaining consistent quality standards.

Multi-sensor Fusion Sorting

Multi-sensor fusion sorting in post-harvest technology combines optical sensors, near-infrared spectroscopy, and X-ray imaging to enhance defect detection accuracy beyond manual sorting limitations. This integration enables precise identification of external and internal defects, increasing sorting efficiency and reducing product loss compared to traditional manual methods.

Minimal-touch Post-harvest Handling

Manual sorting relies on human inspectors to identify and remove defects, offering precise judgment but increasing the risk of contamination through multiple touchpoints. Optical sorting utilizes advanced sensors and cameras to quickly detect and separate defective produce, enabling minimal-touch post-harvest handling that enhances hygiene and operational efficiency.

Manual sorting vs optical sorting for defect removal Infographic

agridif.com

agridif.com