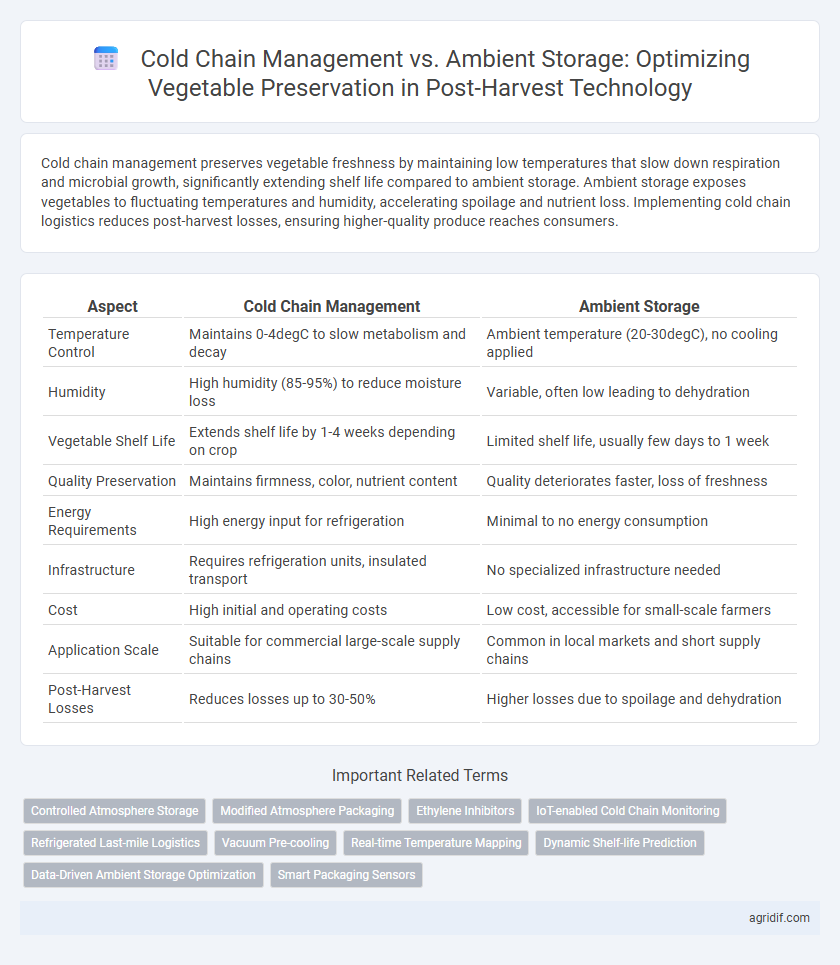

Cold chain management preserves vegetable freshness by maintaining low temperatures that slow down respiration and microbial growth, significantly extending shelf life compared to ambient storage. Ambient storage exposes vegetables to fluctuating temperatures and humidity, accelerating spoilage and nutrient loss. Implementing cold chain logistics reduces post-harvest losses, ensuring higher-quality produce reaches consumers.

Table of Comparison

| Aspect | Cold Chain Management | Ambient Storage |

|---|---|---|

| Temperature Control | Maintains 0-4degC to slow metabolism and decay | Ambient temperature (20-30degC), no cooling applied |

| Humidity | High humidity (85-95%) to reduce moisture loss | Variable, often low leading to dehydration |

| Vegetable Shelf Life | Extends shelf life by 1-4 weeks depending on crop | Limited shelf life, usually few days to 1 week |

| Quality Preservation | Maintains firmness, color, nutrient content | Quality deteriorates faster, loss of freshness |

| Energy Requirements | High energy input for refrigeration | Minimal to no energy consumption |

| Infrastructure | Requires refrigeration units, insulated transport | No specialized infrastructure needed |

| Cost | High initial and operating costs | Low cost, accessible for small-scale farmers |

| Application Scale | Suitable for commercial large-scale supply chains | Common in local markets and short supply chains |

| Post-Harvest Losses | Reduces losses up to 30-50% | Higher losses due to spoilage and dehydration |

Introduction to Vegetable Post-Harvest Losses

Vegetable post-harvest losses primarily arise from physiological deterioration, microbial spoilage, and mechanical damage, significantly impacting food security and economic value. Cold chain management slows respiration rates and microbial growth by maintaining optimal low temperatures, effectively extending shelf life compared to ambient storage, which exposes vegetables to fluctuating temperatures and humidity. Implementing cold chain systems reduces weight loss, nutrient degradation, and decay incidence, making it a critical strategy for minimizing post-harvest vegetable losses.

Understanding Cold Chain Management in Agriculture

Cold chain management in agriculture involves maintaining a controlled, low-temperature environment from harvest to consumption, significantly reducing microbial growth and physiological deterioration in vegetables. This system preserves nutritional quality, extends shelf life, and minimizes post-harvest losses compared to ambient storage, where fluctuating temperatures accelerate spoilage and degradation. Efficient cold chain logistics, including refrigerated transport and storage facilities, are critical for sustaining vegetable freshness and market value.

Defining Ambient Storage for Vegetables

Ambient storage for vegetables refers to keeping produce at room temperature without refrigeration, typically ranging from 20degC to 30degC, which affects the shelf life and quality due to higher respiration rates. This method relies on proper ventilation, humidity control, and minimal handling to reduce spoilage but generally results in faster deterioration compared to cold chain management. Cold chain management involves maintaining temperatures between 0degC and 5degC, significantly slowing metabolic processes and microbial growth, thereby extending freshness and marketability beyond the limitations of ambient storage.

Comparative Shelf Life: Cold Chain vs. Ambient Storage

Cold chain management significantly extends the shelf life of vegetables by maintaining optimal low temperatures, typically between 0degC to 4degC, which slows down enzymatic activity and microbial growth. In contrast, ambient storage conditions, often ranging from 20degC to 30degC with higher humidity, accelerate deterioration, resulting in a reduced shelf life often by 50% or more depending on the vegetable type. Studies show that cold chain storage can preserve freshness and nutritional quality up to three times longer compared to ambient storage, making it critical for vegetable preservation in post-harvest technology.

Effects on Nutritional Quality and Food Safety

Cold chain management significantly preserves the nutritional quality of vegetables by maintaining optimal low temperatures, which slows enzymatic activity and microbial growth, thereby reducing vitamin and antioxidant degradation. In contrast, ambient storage often leads to rapid nutrient loss and higher risks of foodborne contamination due to fluctuating temperatures and humidity levels. Effective cold chain systems enhance food safety by minimizing pathogen proliferation, extending shelf life, and maintaining the sensory and nutritional attributes crucial for consumer health.

Cost Analysis: Cold Chain vs. Ambient Storage

Cold chain management for vegetable preservation incurs higher initial capital investment and operational costs due to refrigeration equipment, energy consumption, and maintenance requirements, but it significantly reduces post-harvest losses and maintains quality longer. In contrast, ambient storage involves low upfront costs and minimal energy use but leads to increased spoilage rates and shorter shelf life, resulting in higher overall losses and reduced market value. The cost-benefit analysis favors cold chain systems in high-value or perishable vegetables where extended freshness and reduced wastage justify the expenses.

Environmental Impact and Sustainability Considerations

Cold chain management significantly reduces post-harvest losses in vegetables by maintaining optimal low temperatures, thereby preserving freshness and nutritional quality while minimizing food waste. In contrast, ambient storage is energy-efficient but often results in higher spoilage rates, leading to increased greenhouse gas emissions from discarded produce. Sustainable vegetable preservation benefits from cold chain systems powered by renewable energy sources, balancing environmental impact with extended shelf life and reduced carbon footprints.

Infrastructure Requirements and Challenges

Cold chain management for vegetable preservation demands extensive infrastructure, including refrigerated transport, climate-controlled warehouses, and energy-intensive cooling systems, to maintain optimal temperature and humidity levels. In contrast, ambient storage requires simpler facilities but faces challenges such as higher spoilage rates due to fluctuating environmental conditions and limited control over pests and microbial growth. Both systems must address infrastructure costs and maintenance, with cold chains necessitating reliable power sources and technical expertise, while ambient storage needs effective insulation and ventilation to minimize post-harvest losses.

Case Studies: Success Stories and Failures

Cold chain management significantly extends the shelf life of vegetables by maintaining optimal low temperatures and humidity, as demonstrated in case studies from India where mangoes retained quality for over 30 days compared to ambient storage's 7-10 days. Failures in cold chain systems often stem from inconsistent temperature control and inadequate infrastructure, leading to increased spoilage and economic losses, highlighted by tomato supply chains in sub-Saharan Africa. Successful implementations, such as integrated cold chain networks in the Netherlands, showcase reduced post-harvest losses by up to 40%, reinforcing the critical role of temperature regulation in vegetable preservation versus ambient storage.

Recommendations for Optimal Vegetable Preservation

Cold chain management significantly reduces enzymatic activity and microbial growth in vegetables by maintaining temperatures between 0degC and 7degC, thereby extending shelf life up to three times compared to ambient storage at 20degC to 25degC. For optimal vegetable preservation, it is recommended to integrate rapid cooling techniques such as hydro-cooling or forced-air cooling immediately after harvest to minimize field heat. Implementing insulated packaging combined with cold chain logistics ensures consistent temperature control, maximizing freshness and nutrient retention during transportation and storage.

Related Important Terms

Controlled Atmosphere Storage

Controlled Atmosphere Storage in cold chain management significantly extends the shelf life of vegetables by precisely regulating oxygen, carbon dioxide, and humidity levels, thereby slowing respiration and microbial growth compared to ambient storage. This technology minimizes nutrient loss and quality degradation, ensuring superior freshness and reduced post-harvest waste throughout the supply chain.

Modified Atmosphere Packaging

Modified Atmosphere Packaging (MAP) significantly extends the shelf life of vegetables by altering gas compositions to reduce respiration rates and delay spoilage compared to ambient storage, which lacks controlled environmental factors. Cold chain management combined with MAP enhances quality preservation by maintaining low temperatures and optimal atmospheric conditions, minimizing microbial growth and enzymatic activity more effectively than either method alone.

Ethylene Inhibitors

Cold chain management effectively slows down the ripening and senescence of vegetables by maintaining low temperatures and integrating ethylene inhibitors like 1-MCP, which block ethylene receptors and delay spoilage. In contrast, ambient storage lacks temperature control and relies mainly on ethylene inhibitors that partially reduce ethylene effects but cannot fully compensate for the accelerated metabolic activity at higher temperatures.

IoT-enabled Cold Chain Monitoring

IoT-enabled cold chain monitoring significantly enhances vegetable preservation by maintaining optimal temperature and humidity levels throughout post-harvest handling, reducing spoilage and extending shelf life compared to ambient storage. Real-time data collection and automated alerts enable proactive management of cold storage conditions, ensuring quality retention and minimizing economic losses in the supply chain.

Refrigerated Last-mile Logistics

Refrigerated last-mile logistics significantly enhance vegetable preservation by maintaining optimal low temperatures throughout distribution, minimizing spoilage compared to ambient storage, which exposes produce to fluctuating temperatures and accelerates quality degradation. Effective cold chain management ensures extended shelf life, reduced microbial growth, and sustained freshness, crucial for post-harvest vegetable supply chains.

Vacuum Pre-cooling

Vacuum pre-cooling significantly enhances cold chain management by rapidly removing field heat from vegetables, preserving freshness and extending shelf life compared to ambient storage where higher temperatures accelerate respiration and spoilage. Efficient integration of vacuum pre-cooling within cold chain logistics minimizes microbial growth and quality deterioration, ensuring vegetables reach consumers with optimal texture and nutritional value.

Real-time Temperature Mapping

Real-time temperature mapping in cold chain management ensures precise monitoring and control, significantly reducing spoilage and extending the shelf life of vegetables compared to ambient storage. This technology enables prompt detection of temperature fluctuations, maintaining optimal storage conditions and preserving nutritional quality during post-harvest handling.

Dynamic Shelf-life Prediction

Cold chain management significantly extends vegetable shelf-life by maintaining optimal low temperatures and humidity levels, which slow down respiration and microbial growth compared to ambient storage that accelerates spoilage due to fluctuating environmental conditions. Dynamic shelf-life prediction models integrated with cold chain data provide accurate, real-time estimations of freshness duration, enabling precise inventory control and reducing post-harvest losses in vegetable supply chains.

Data-Driven Ambient Storage Optimization

Data-driven ambient storage optimization leverages real-time monitoring of temperature, humidity, and gas composition to extend vegetable shelf life while minimizing energy consumption compared to traditional cold chain management. Advanced sensor technology and predictive analytics enable precise environmental control, reducing spoilage and maintaining nutritional quality without the high costs associated with refrigeration-based preservation.

Smart Packaging Sensors

Smart packaging sensors integrated into cold chain management provide real-time monitoring of temperature, humidity, and gas composition, significantly reducing spoilage and extending the shelf life of vegetables compared to ambient storage. These sensors enable precise environmental control and timely interventions, enhancing freshness and reducing post-harvest losses in the vegetable supply chain.

Cold chain management vs ambient storage for vegetable preservation Infographic

agridif.com

agridif.com