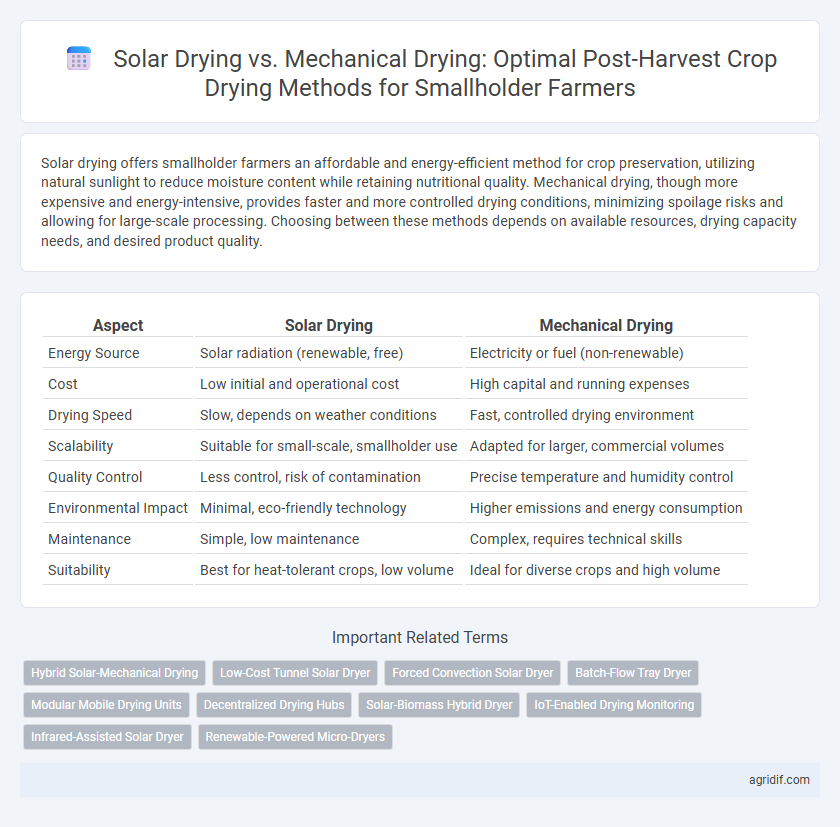

Solar drying offers smallholder farmers an affordable and energy-efficient method for crop preservation, utilizing natural sunlight to reduce moisture content while retaining nutritional quality. Mechanical drying, though more expensive and energy-intensive, provides faster and more controlled drying conditions, minimizing spoilage risks and allowing for large-scale processing. Choosing between these methods depends on available resources, drying capacity needs, and desired product quality.

Table of Comparison

| Aspect | Solar Drying | Mechanical Drying |

|---|---|---|

| Energy Source | Solar radiation (renewable, free) | Electricity or fuel (non-renewable) |

| Cost | Low initial and operational cost | High capital and running expenses |

| Drying Speed | Slow, depends on weather conditions | Fast, controlled drying environment |

| Scalability | Suitable for small-scale, smallholder use | Adapted for larger, commercial volumes |

| Quality Control | Less control, risk of contamination | Precise temperature and humidity control |

| Environmental Impact | Minimal, eco-friendly technology | Higher emissions and energy consumption |

| Maintenance | Simple, low maintenance | Complex, requires technical skills |

| Suitability | Best for heat-tolerant crops, low volume | Ideal for diverse crops and high volume |

Introduction to Crop Drying Methods in Smallholder Agriculture

Solar drying harnesses natural sunlight and ambient air to reduce crop moisture content, offering an energy-efficient and low-cost method ideal for smallholder farmers with limited resources. Mechanical drying employs controlled heat and forced airflow, providing faster and more uniform drying but requires higher capital investment and operational costs. Selecting an appropriate drying method depends on crop type, climatic conditions, and resource availability to ensure quality preservation and minimize post-harvest losses.

Principles and Processes of Solar Drying

Solar drying for smallholder crops relies on the principle of converting solar radiation into thermal energy, which raises the temperature and reduces moisture content within the drying chamber or direct exposure area. The process involves natural convection or forced air circulation to enhance moisture evaporation from crops, ensuring preservation of nutritional quality while minimizing energy costs. Solar dryers use either direct solar radiation or greenhouse-type structures with transparent covers to optimize heat retention and airflow, offering a sustainable alternative to mechanical drying methods that require external power sources.

Mechanisms and Technologies of Mechanical Drying

Mechanical drying for smallholder crop drying utilizes controlled heat and airflow to reduce moisture content efficiently, leveraging technologies like forced-air dryers, rotary drum dryers, and fluidized bed dryers. These systems enable precise temperature regulation and uniform drying, minimizing microbial proliferation and quality degradation often encountered in solar drying methods. Innovations in sensor integration and energy-efficient heating techniques enhance the reliability and scalability of mechanical drying for diverse crop types in post-harvest management.

Cost Analysis: Solar vs Mechanical Drying for Small Farmers

Solar drying incurs minimal operational costs, relying primarily on sunlight, making it highly cost-effective for smallholder farmers with limited capital. Mechanical drying requires significant initial investment and ongoing expenses for fuel, electricity, and maintenance, which can be prohibitive for small-scale users. Cost analysis reveals solar drying as the preferred low-cost method, while mechanical drying offers faster processing but at higher financial risk to small farmers.

Energy Efficiency and Sustainability Considerations

Solar drying offers significant energy efficiency advantages for smallholder crop drying by utilizing abundant solar radiation, reducing reliance on external power sources and lowering operational costs. Mechanical drying, while providing faster and more controlled drying processes, often demands high energy inputs from fossil fuels or electricity, raising sustainability concerns in resource-constrained rural settings. Prioritizing solar drying can enhance sustainability by minimizing greenhouse gas emissions and leveraging renewable energy, whereas mechanical drying systems require careful energy management and integration of renewable energy sources to improve environmental outcomes.

Impacts on Crop Quality and Nutritional Value

Solar drying preserves the nutritional value of smallholder crops by maintaining natural antioxidants and vitamins due to its gentle drying process at low temperatures. Mechanical drying offers faster moisture removal but can cause nutrient degradation and color changes from higher heat exposure. Selecting the appropriate drying method directly influences crop quality, shelf life, and market value for smallholder farmers.

Scalability and Accessibility for Rural Communities

Solar drying offers a cost-effective and scalable solution for smallholder crop drying, leveraging abundant sunlight to reduce post-harvest losses without requiring complex infrastructure. Mechanical drying provides faster and more controlled drying conditions but often entails higher initial investment and operational costs, limiting accessibility for rural communities with constrained financial resources. Prioritizing solar drying enhances sustainability and empowers smallholders by utilizing locally available resources, ensuring greater adoption and scalability in decentralized, off-grid agricultural settings.

Environmental Footprint: Solar vs Mechanical Dryers

Solar drying for smallholder crops significantly reduces environmental footprint by utilizing renewable sunlight energy, eliminating fossil fuel consumption and minimizing greenhouse gas emissions. Mechanical dryers, while offering faster drying times and greater control over parameters, rely heavily on electricity or fuel, contributing to higher carbon emissions and energy costs. Solar drying systems promote sustainable agriculture through carbon-neutral operation, whereas mechanical dryers pose environmental challenges due to their dependency on non-renewable energy sources.

Maintenance and Technical Skills Required

Solar drying for smallholder crops demands minimal maintenance and basic technical knowledge, making it accessible and cost-effective for farmers with limited resources. Mechanical drying systems require regular maintenance, skilled operators, and technical expertise to manage machinery, troubleshoot issues, and ensure consistent drying conditions. The choice between solar and mechanical drying significantly impacts operational complexity and long-term sustainability for smallholder farmers.

Decision Factors for Smallholder Farmers in Choosing a Drying Method

Smallholder farmers prioritize cost-effectiveness, energy availability, and drying efficiency when choosing between solar and mechanical drying methods. Solar drying offers low operational costs and utilizes renewable energy, but is weather-dependent and slower, while mechanical drying provides faster, controlled drying conditions at higher fuel or electricity expenses. Factors such as crop type, scale of production, local climate, and access to technology influence the optimal drying method for preserving crop quality and minimizing post-harvest losses.

Related Important Terms

Hybrid Solar-Mechanical Drying

Hybrid solar-mechanical drying integrates the energy efficiency of solar drying with the controlled environment of mechanical drying, optimizing moisture removal while reducing energy consumption for smallholder crop processing. This method enhances drying uniformity, reduces post-harvest losses, and improves crop quality by leveraging solar energy during peak sunlight and mechanical systems during off-peak periods.

Low-Cost Tunnel Solar Dryer

Low-cost tunnel solar dryers offer smallholder farmers an energy-efficient and affordable method for post-harvest crop drying, reducing moisture content while preserving nutritional quality and minimizing spoilage compared to traditional sun drying. Mechanical drying, although faster and more controllable, entails higher operational costs and energy consumption, making solar tunnel dryers a sustainable alternative in resource-limited settings.

Forced Convection Solar Dryer

Forced convection solar dryers offer smallholder farmers an energy-efficient and cost-effective alternative to mechanical drying by utilizing solar energy combined with controlled airflow to enhance drying rates and preserve crop quality. These dryers reduce moisture content uniformly while minimizing contamination risks, promoting better post-harvest management compared to fuel-dependent mechanical dryers.

Batch-Flow Tray Dryer

Batch-flow tray dryers offer smallholder farmers an energy-efficient mechanical drying solution that ensures uniform moisture removal and improved crop quality compared to traditional solar drying methods. Solar drying depends heavily on weather conditions and can lead to inconsistent drying, whereas batch-flow tray dryers provide controlled temperature and airflow, enhancing drying speed and reducing post-harvest losses.

Modular Mobile Drying Units

Modular mobile drying units utilizing solar drying offer smallholder farmers an energy-efficient and cost-effective solution with reduced carbon emissions compared to mechanical drying systems that rely on fossil fuels. These units enhance drying uniformity and portability, enabling on-site processing while minimizing post-harvest losses and maintaining crop quality through controlled drying conditions.

Decentralized Drying Hubs

Decentralized drying hubs leveraging solar drying offer smallholder farmers energy-efficient, low-cost solutions that reduce post-harvest losses while preserving crop quality through gentle drying processes. Mechanical drying systems, though faster and controllable, require higher capital investment and energy inputs, making them less accessible for decentralized applications targeting small-scale producers.

Solar-Biomass Hybrid Dryer

Solar-biomass hybrid dryers combine the cost-efficiency and environmental benefits of solar drying with the reliability and faster drying rates of biomass energy, making them ideal for smallholder crop drying where intermittent sunlight limits solar alone. These hybrid systems enhance drying uniformity and reduce post-harvest losses by maintaining stable temperatures and humidity levels, improving crop quality and shelf life compared to conventional mechanical or solar-only dryers.

IoT-Enabled Drying Monitoring

IoT-enabled solar drying systems provide smallholder farmers with real-time data on temperature, humidity, and drying rates, significantly enhancing efficiency and crop quality compared to traditional methods. Mechanical drying systems integrated with IoT sensors allow precise control and automated adjustments, reducing energy consumption and post-harvest losses while improving traceability and decision-making.

Infrared-Assisted Solar Dryer

Infrared-assisted solar dryers enhance smallholder crop drying by combining solar energy with infrared radiation, accelerating moisture removal while preserving nutritional quality better than traditional solar drying. Compared to mechanical drying, this technology reduces energy consumption and operational costs, making it a sustainable and efficient option for post-harvest moisture control.

Renewable-Powered Micro-Dryers

Renewable-powered micro-dryers, such as solar drying systems, offer energy-efficient, low-cost solutions for smallholder crop drying by utilizing abundant solar radiation and reducing dependency on fossil fuels. Mechanical drying, while faster and more controllable, often incurs higher operational costs and relies on electricity or fuel, making renewable-powered micro-dryers more sustainable and accessible for decentralized post-harvest processing.

Solar Drying vs Mechanical Drying for smallholder crop drying Infographic

agridif.com

agridif.com