Mechanical grading in post-harvest technology relies on physical parameters such as size, weight, and shape to sort produce, ensuring uniformity based on tangible attributes. Optical grading employs advanced imaging and sensor technology to assess external quality factors like color, texture, and surface defects, providing more precise and non-destructive evaluation. Combining both mechanical and optical grading techniques enhances accuracy and efficiency in quality sorting, reducing waste and improving market value.

Table of Comparison

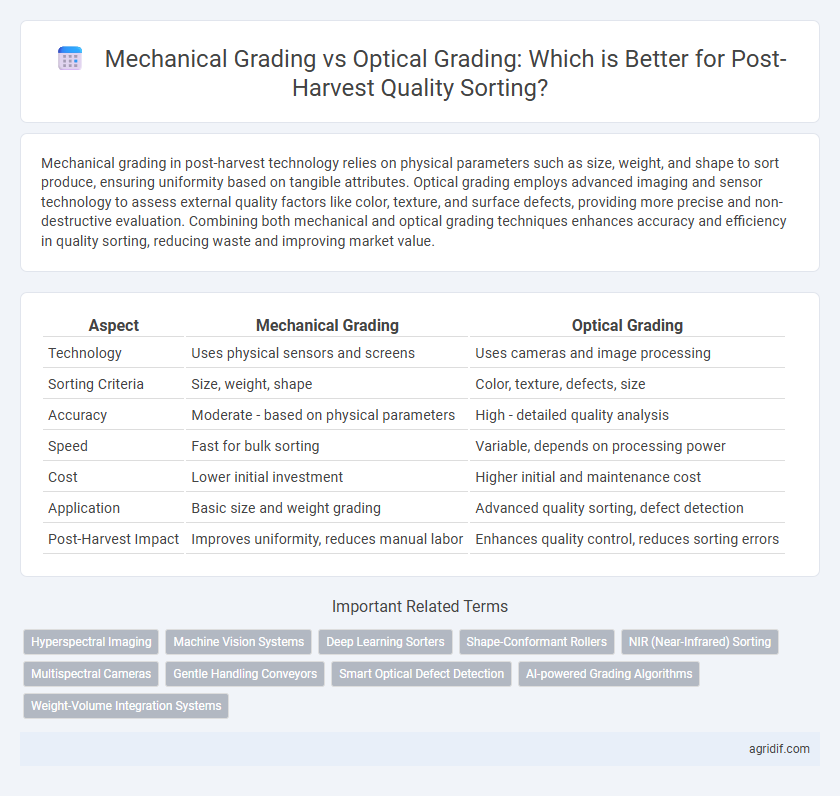

| Aspect | Mechanical Grading | Optical Grading |

|---|---|---|

| Technology | Uses physical sensors and screens | Uses cameras and image processing |

| Sorting Criteria | Size, weight, shape | Color, texture, defects, size |

| Accuracy | Moderate - based on physical parameters | High - detailed quality analysis |

| Speed | Fast for bulk sorting | Variable, depends on processing power |

| Cost | Lower initial investment | Higher initial and maintenance cost |

| Application | Basic size and weight grading | Advanced quality sorting, defect detection |

| Post-Harvest Impact | Improves uniformity, reduces manual labor | Enhances quality control, reduces sorting errors |

Introduction to Post-Harvest Grading Technologies

Mechanical grading utilizes physical parameters such as size, weight, and shape for sorting agricultural produce, ensuring consistency in commercial classification. Optical grading employs advanced imaging technologies like hyperspectral cameras and machine vision systems to analyze color, texture, and surface defects with high precision. Integration of these post-harvest grading technologies enhances sorting efficiency, reduces human error, and maintains product quality throughout the supply chain.

Mechanical Grading: Principles and Processes

Mechanical grading in post-harvest technology involves the use of physical forces such as size, weight, and shape to sort agricultural products. Common mechanisms include sieves, rollers, and gravity separators that categorize produce based on dimensional and density differences. This method ensures consistent quality by efficiently removing undersized, oversized, or damaged items prior to packing and distribution.

Optical Grading: Advanced Technology Overview

Optical grading systems utilize advanced imaging technologies such as hyperspectral cameras, near-infrared sensors, and machine learning algorithms to accurately assess the quality attributes of agricultural products, including size, color, texture, and internal defects. These systems enable faster and more precise sorting compared to mechanical graders by providing non-destructive analysis and reducing human error. Integration of artificial intelligence enhances real-time decision-making, improving overall post-harvest quality management and supply chain efficiency.

Effectiveness in Sorting Accuracy

Mechanical grading relies on size and weight metrics to sort produce but often falls short in detecting internal defects and color variations, limiting sorting accuracy. Optical grading employs advanced imaging and hyperspectral sensors to capture detailed surface and internal quality attributes, significantly enhancing accuracy in quality classification. Studies indicate optical grading can improve sorting precision by up to 30%, reducing post-harvest losses and optimizing supply chain quality control.

Speed and Throughput Comparison

Mechanical grading systems rely on physical measurements such as size and weight, enabling rapid sorting with moderate throughput suitable for bulk handling. Optical grading employs advanced imaging technologies and sensors to evaluate external quality attributes like color, shape, and defects, offering higher precision but often at slower speeds and reduced throughput. Integrating optical systems with mechanical sorting mechanisms can optimize speed and accuracy, maximizing overall post-harvest sorting efficiency.

Labor and Operational Costs

Mechanical grading systems in post-harvest technology typically involve higher labor costs due to manual adjustments and maintenance requirements, increasing operational expenses. Optical grading utilizes advanced imaging technology and automation, significantly reducing labor dependency and improving sorting precision. Consequently, optical grading offers lower long-term operational costs and enhanced throughput efficiency compared to conventional mechanical methods.

Consistency and Quality Assurance

Mechanical grading in post-harvest technology offers consistent sorting based on size and weight, ensuring uniformity in bulk produce processing. Optical grading systems utilize advanced imaging and spectral analysis to detect surface defects and internal quality attributes, enhancing precision and reducing human error. Combining both methods maximizes quality assurance by leveraging mechanical reliability and optical accuracy for superior grading outcomes.

Maintenance and Equipment Lifespan

Mechanical grading systems require regular maintenance to prevent wear and tear from physical contact with produce, often involving frequent calibration and replacement of moving parts to ensure accuracy. Optical grading technology, utilizing advanced sensors and cameras, experiences less mechanical stress, resulting in longer equipment lifespan and reduced downtime. Investing in optical grading can optimize operational efficiency by minimizing maintenance costs and extending machinery durability in quality sorting processes.

Suitability for Different Crops

Mechanical grading excels in handling bulky crops like potatoes and root vegetables due to its robust size and weight-based sorting capabilities, ensuring uniformity in physical dimensions. Optical grading, leveraging advanced imaging and spectral analysis, suits delicate fruits and vegetables such as tomatoes and apples by detecting color, texture, and surface defects with high precision. Combining both methods enhances sorting accuracy across diverse crop types, optimizing quality control in post-harvest processing.

Future Trends in Post-Harvest Grading Systems

Mechanical grading systems rely on size, weight, and shape measurements to sort harvested produce efficiently but often lack precision in quality detection. Optical grading systems utilize advanced imaging technologies, such as hyperspectral cameras and machine learning algorithms, to assess internal quality attributes like ripeness, defects, and sugar content with higher accuracy. Future trends in post-harvest grading emphasize integrating artificial intelligence, multispectral imaging, and IoT connectivity to enhance real-time sorting efficiency, reduce waste, and optimize supply chain management.

Related Important Terms

Hyperspectral Imaging

Hyperspectral imaging in post-harvest technology offers superior optical grading by capturing detailed spectral data that enables precise quality sorting based on internal and external product attributes. Unlike mechanical grading, hyperspectral imaging accurately detects defects, moisture content, and chemical composition, enhancing sorting efficiency and reducing post-harvest losses.

Machine Vision Systems

Machine vision systems in optical grading leverage advanced image processing algorithms and multispectral cameras to assess fruit and vegetable quality with high precision, detecting defects, size, and color variability beyond the capabilities of traditional mechanical grading. This technology enhances sorting accuracy, reduces human error, and increases throughput by instantly analyzing multiple parameters simultaneously during post-harvest processing.

Deep Learning Sorters

Mechanical grading relies on size and weight measurements for sorting produce, often lacking precision in detecting internal defects or subtle quality variations. Deep learning sorters employ advanced image recognition algorithms and convolutional neural networks to analyze color, texture, and shape, enabling highly accurate, real-time quality assessment and classification in post-harvest sorting processes.

Shape-Conformant Rollers

Shape-conformant rollers in mechanical grading systems enhance quality sorting by precisely aligning produce based on contour, ensuring uniform size and shape classification. Optical grading complements this by using advanced imaging to detect surface defects and color variations, together improving accuracy and efficiency in post-harvest handling.

NIR (Near-Infrared) Sorting

Near-Infrared (NIR) sorting significantly enhances post-harvest quality grading by accurately detecting internal attributes such as moisture, sugar content, and defects that mechanical grading methods cannot assess. This optical grading technology increases sorting precision and efficiency, reducing product waste and ensuring consistent quality in agricultural produce.

Multispectral Cameras

Multispectral cameras enhance optical grading by capturing detailed spectral information across various wavelengths, enabling precise detection of quality attributes such as ripeness, defects, and contaminants that mechanical grading often misses. This technology improves sorting accuracy and efficiency in post-harvest processes, reducing waste and ensuring consistent product quality.

Gentle Handling Conveyors

Mechanical grading relies on size and weight for quality sorting but can cause damage to delicate produce, whereas optical grading utilizes advanced imaging technology to assess external and internal quality attributes with higher precision. Gentle handling conveyors, integrated in optical grading systems, minimize physical stress on fruits and vegetables, preserving their integrity and extending shelf life.

Smart Optical Defect Detection

Smart optical defect detection in post-harvest technology revolutionizes quality sorting by utilizing advanced imaging sensors and machine learning algorithms to accurately identify defects such as bruises, discoloration, and foreign materials. This method surpasses traditional mechanical grading by enabling non-destructive, high-throughput, and precise sorting that significantly enhances efficiency and reduces product waste.

AI-powered Grading Algorithms

AI-powered grading algorithms enhance optical grading systems by enabling precise, real-time analysis of fruit size, shape, and surface defects, outperforming traditional mechanical graders that rely solely on physical measurements. Integrating machine learning models with high-resolution imaging facilitates accurate, consistent quality sorting, reducing waste and improving market value in post-harvest technology.

Weight-Volume Integration Systems

Mechanical grading systems predominantly utilize weight and volume measurements to categorize produce, offering cost-effective and reliable sorting based on density and size parameters. Optical grading integrated with weight-volume data enhances accuracy by combining visual quality assessment with precise weight-volume metrics, optimizing post-harvest sorting efficiency.

Mechanical Grading vs Optical Grading for Quality Sorting Infographic

agridif.com

agridif.com