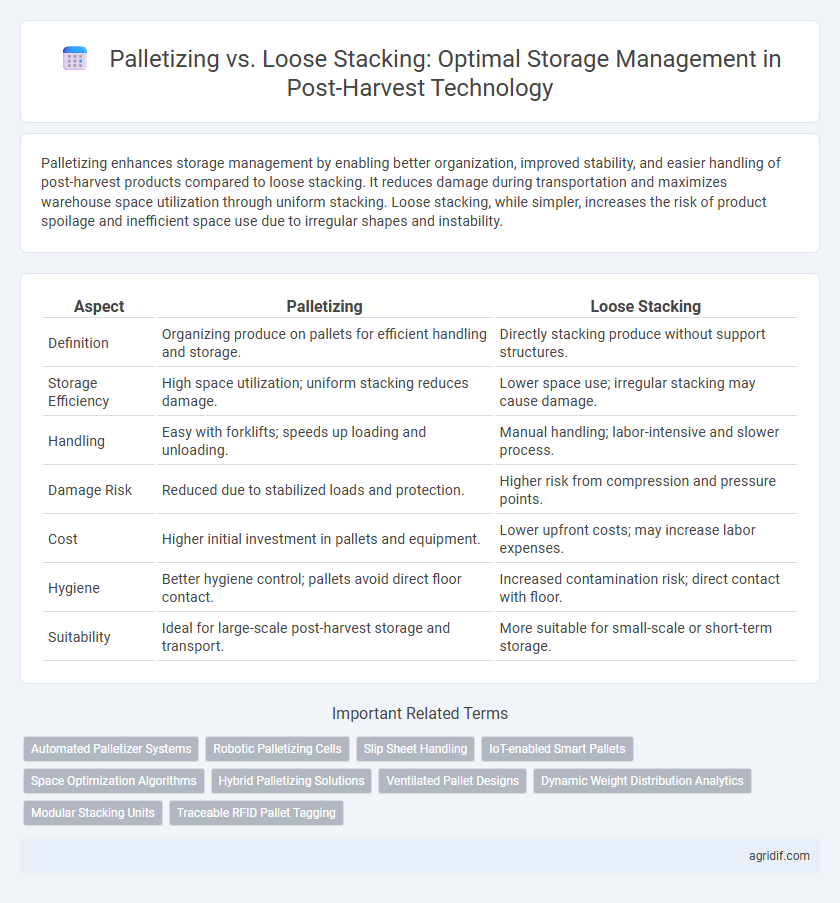

Palletizing enhances storage management by enabling better organization, improved stability, and easier handling of post-harvest products compared to loose stacking. It reduces damage during transportation and maximizes warehouse space utilization through uniform stacking. Loose stacking, while simpler, increases the risk of product spoilage and inefficient space use due to irregular shapes and instability.

Table of Comparison

| Aspect | Palletizing | Loose Stacking |

|---|---|---|

| Definition | Organizing produce on pallets for efficient handling and storage. | Directly stacking produce without support structures. |

| Storage Efficiency | High space utilization; uniform stacking reduces damage. | Lower space use; irregular stacking may cause damage. |

| Handling | Easy with forklifts; speeds up loading and unloading. | Manual handling; labor-intensive and slower process. |

| Damage Risk | Reduced due to stabilized loads and protection. | Higher risk from compression and pressure points. |

| Cost | Higher initial investment in pallets and equipment. | Lower upfront costs; may increase labor expenses. |

| Hygiene | Better hygiene control; pallets avoid direct floor contact. | Increased contamination risk; direct contact with floor. |

| Suitability | Ideal for large-scale post-harvest storage and transport. | More suitable for small-scale or short-term storage. |

Introduction to Post-Harvest Storage Methods

Palletizing improves post-harvest storage by facilitating better air circulation and reducing product damage compared to loose stacking, which often leads to increased spoilage due to restricted airflow and mechanical injuries. Effective palletizing enhances inventory management, optimizes warehouse space, and supports automated handling systems, crucial for maintaining the quality of perishable commodities. Storage methods leveraging pallets also enable easier monitoring of humidity and temperature, extending the shelf life of stored produce.

Understanding Palletizing in Agriculture

Palletizing in agriculture enhances post-harvest storage management by improving product handling efficiency and minimizing damage during transport. Standardized pallets facilitate better air circulation, reducing spoilage and maintaining crop quality compared to loose stacking methods. Implementing palletizing also optimizes warehouse space utilization and streamlines inventory tracking through uniform containerization.

Exploring Loose Stacking Techniques

Loose stacking techniques in post-harvest storage optimize airflow and reduce mechanical damage to produce, enhancing shelf life and quality. Unlike palletizing, which concentrates weight and limits ventilation, loose stacking allows for better temperature and humidity control, crucial for perishable goods. Effective loose stacking improves storage efficiency by minimizing bruising and decay, ultimately reducing post-harvest losses.

Efficiency Comparison: Palletizing vs Loose Stacking

Palletizing enhances storage efficiency by enabling uniform stacking, reducing space wastage by up to 30% compared to loose stacking, which often leads to irregular arrangement and increased handling time. The standardized dimensions of pallet loads facilitate quicker loading, unloading, and inventory management, improving overall operational speed by approximately 25%. Conversely, loose stacking necessitates more manual labor and risk of product damage, lowering efficiency in long-term storage and transport logistics.

Impact on Crop Quality and Shelf Life

Palletizing enhances crop quality and shelf life by promoting better air circulation, reducing mechanical damage, and minimizing contamination compared to loose stacking. Improved ventilation through palletized storage decreases moisture accumulation, thereby slowing microbial growth and spoilage. In contrast, loose stacking increases the risk of bruising and uneven ripening, leading to accelerated deterioration and shorter shelf life.

Labor and Cost Considerations

Palletizing in post-harvest storage significantly reduces labor requirements by facilitating easier handling, transportation, and inventory management compared to loose stacking. The initial investment in pallets and equipment may increase upfront costs but results in long-term savings through minimized product damage and faster processing times. Loose stacking incurs lower immediate expenses but often leads to higher labor costs and inefficiencies due to increased handling difficulties and spoilage risks.

Space Utilization and Storage Capacity

Palletizing enhances space utilization by allowing uniform stacking and efficient use of vertical space, resulting in increased storage capacity compared to loose stacking. Loose stacking often leads to irregular stacking patterns and wasted space due to inconsistent load shapes and sizes. Optimizing palletized loads improves warehouse organization and maximizes cubic storage efficiency in post-harvest storage management.

Handling and Transportation Benefits

Palletizing fosters efficient handling and streamlined transportation by enabling standardized stacking and easy movement with forklifts, reducing labor effort and damage risks during transit. Loose stacking, while flexible for irregular produce, increases handling time and the likelihood of product bruising due to manual sorting and frequent repositioning. Optimal post-harvest management favors palletizing for bulk storage to enhance load stability, minimize spoilage, and improve logistics efficiency.

Safety and Risk Management

Palletizing post-harvest produce enhances storage safety by reducing product damage and minimizing contamination risks through organized stacking and improved airflow. Loose stacking increases the likelihood of physical injuries and product spoilage due to instability and difficulty in handling, elevating overall risk. Strategic use of pallets supports efficient inventory management and mitigates hazards associated with manual labor and equipment use in storage facilities.

Best Practices for Choosing Storage Methods

Palletizing ensures better airflow, reduced contamination risk, and easier handling, making it ideal for long-term storage of perishable produce. Loose stacking allows for flexible space utilization but increases vulnerability to physical damage and pest infestation, requiring stringent monitoring. Choosing the right storage method depends on product type, storage duration, and facility resources to optimize post-harvest quality and shelf life.

Related Important Terms

Automated Palletizer Systems

Automated palletizer systems enhance post-harvest storage management by increasing efficiency, reducing labor costs, and minimizing product damage compared to loose stacking. These systems enable precise, uniform stacking of produce, optimizing warehouse space utilization and improving inventory control in cold storage facilities.

Robotic Palletizing Cells

Robotic palletizing cells enhance storage management by precisely stacking products on pallets, improving space efficiency and reducing damage compared to loose stacking. This automation increases throughput, optimizes warehouse organization, and supports consistent post-harvest product quality control.

Slip Sheet Handling

Palletizing offers structured load stability and easier mechanized handling, significantly reducing product damage and increasing warehouse efficiency compared to loose stacking, which often leads to unstable loads and higher handling costs. Slip sheet handling enhances palletizing by providing a cost-effective, lightweight alternative to traditional pallets, improving space utilization and minimizing environmental impact in post-harvest storage management.

IoT-enabled Smart Pallets

IoT-enabled smart pallets enhance post-harvest storage management by providing real-time monitoring of temperature, humidity, and product conditions, ensuring optimal preservation compared to loose stacking. The integration of sensors and data analytics in smart pallets reduces spoilage, improves inventory tracking, and optimizes warehouse space utilization for perishable goods.

Space Optimization Algorithms

Palletizing enhances storage efficiency by systematically organizing produce into uniform layers, allowing space optimization algorithms to precisely calculate and maximize cubic utilization in warehouses, reducing air gaps and minimizing damage risk. In contrast, loose stacking leads to irregular arrangements that complicate algorithmic space optimization, resulting in inefficient use of storage volume and increased deterioration rates due to inconsistent airflow and pressure distribution.

Hybrid Palletizing Solutions

Hybrid palletizing solutions combine the efficiency and stability of palletizing with the flexibility of loose stacking, optimizing space utilization and reducing product damage during post-harvest storage. Integrating automated palletizing systems with strategic loose stacking methods allows for enhanced inventory management, faster handling times, and improved airflow for perishable goods.

Ventilated Pallet Designs

Ventilated pallet designs enhance airflow and reduce moisture accumulation compared to loose stacking, significantly minimizing post-harvest losses in perishable produce such as fruits and vegetables. Optimizing storage management through ventilated pallets improves temperature regulation and extends shelf life by preventing fungal growth and spoilage.

Dynamic Weight Distribution Analytics

Dynamic weight distribution analytics reveal that palletizing enhances storage stability by evenly distributing load weight, reducing product damage and optimizing space utilization compared to loose stacking. Implementing palletizing in post-harvest storage improves inventory handling efficiency through precise load monitoring and minimizes risks associated with uneven weight distribution.

Modular Stacking Units

Modular stacking units enhance storage efficiency by enabling organized, space-saving palletizing, which reduces product damage and facilitates easier inventory management compared to loose stacking. Palletizing ensures uniform load distribution and streamlined handling, optimizing post-harvest storage conditions and minimizing spoilage.

Traceable RFID Pallet Tagging

Palletizing enhances storage management by enabling efficient handling, streamlined inventory control, and reduced product damage compared to loose stacking, especially when integrated with traceable RFID pallet tagging. RFID technology provides real-time tracking and accurate data capture, improving traceability, minimizing losses, and optimizing supply chain operations in post-harvest storage environments.

Palletizing vs loose stacking for storage management Infographic

agridif.com

agridif.com