Vacuum cooling offers rapid and efficient cooling for leafy greens by removing heat through evaporation in a low-pressure environment, significantly reducing temperature within minutes. Room cooling relies on ambient air circulation and takes longer to lower the temperature, which may increase the risk of moisture loss and microbial growth. The faster cooling of vacuum systems enhances shelf life and maintains the freshness and crispness of leafy greens better than traditional room cooling methods.

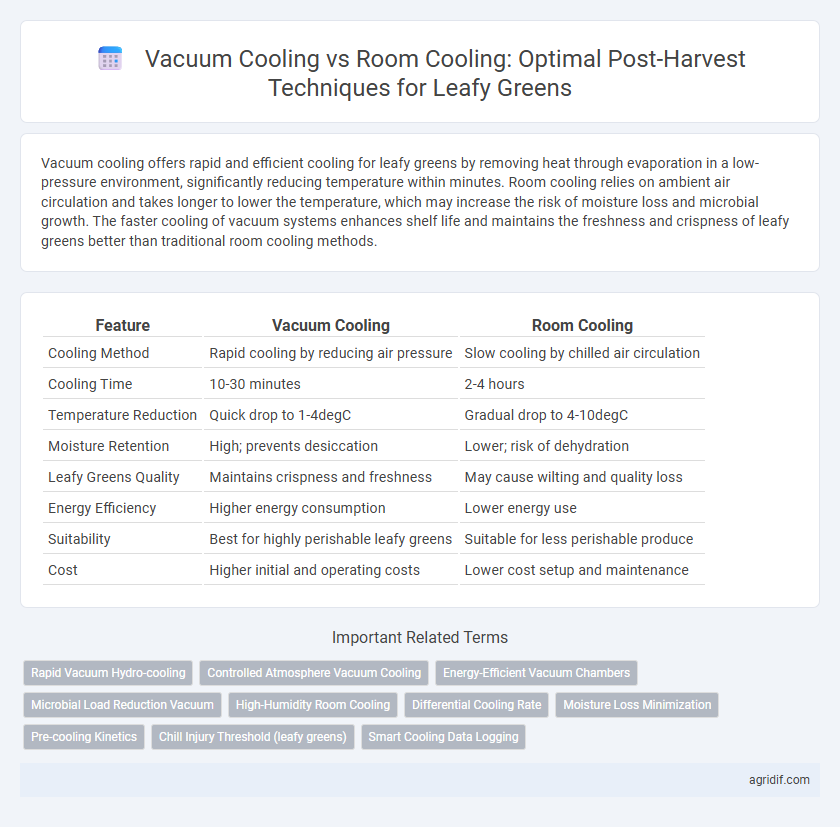

Table of Comparison

| Feature | Vacuum Cooling | Room Cooling |

|---|---|---|

| Cooling Method | Rapid cooling by reducing air pressure | Slow cooling by chilled air circulation |

| Cooling Time | 10-30 minutes | 2-4 hours |

| Temperature Reduction | Quick drop to 1-4degC | Gradual drop to 4-10degC |

| Moisture Retention | High; prevents desiccation | Lower; risk of dehydration |

| Leafy Greens Quality | Maintains crispness and freshness | May cause wilting and quality loss |

| Energy Efficiency | Higher energy consumption | Lower energy use |

| Suitability | Best for highly perishable leafy greens | Suitable for less perishable produce |

| Cost | Higher initial and operating costs | Lower cost setup and maintenance |

Introduction to Post-Harvest Cooling Methods for Leafy Greens

Vacuum cooling and room cooling are critical post-harvest technologies for maintaining the freshness of leafy greens by rapidly reducing field heat. Vacuum cooling operates by evaporating water under reduced pressure, achieving cooling within minutes, which significantly slows down respiration rates and microbial growth. In contrast, room cooling relies on air circulation at ambient cold temperatures, requiring several hours, thus posing a higher risk of moisture loss and quality degradation.

Understanding Vacuum Cooling: Principles and Process

Vacuum cooling rapidly reduces the temperature of leafy greens by lowering the atmospheric pressure around the product, causing water to evaporate and absorb heat through latent heat of vaporization. This method efficiently removes field heat within minutes, maintaining freshness and extending shelf life by minimizing microbial growth and enzymatic activity. Compared to traditional room cooling, vacuum cooling ensures uniform temperature reduction, preventing quality degradation and moisture loss in delicate leafy greens.

Overview of Room Cooling: How It Works

Room cooling for leafy greens operates by circulating chilled air around the produce in a controlled environment, gradually lowering the temperature to slow respiration and delay spoilage. This method relies on maintaining optimal humidity levels, typically between 90-95%, to prevent dehydration and wilting. Although slower than vacuum cooling, room cooling is energy-efficient and suitable for larger quantities or delicate greens sensitive to rapid temperature changes.

Cooling Efficiency: Vacuum vs Room Cooling

Vacuum cooling rapidly reduces the temperature of leafy greens by evaporative cooling under low pressure, achieving temperatures close to the dew point within minutes, which significantly slows down respiration and microbial growth. Room cooling relies on ambient air temperature and natural convection, often requiring several hours to reach desired cooling levels, resulting in less efficient heat removal and increased water loss through transpiration. The superior cooling efficiency of vacuum systems leads to prolonged shelf life, reduced weight loss, and better preservation of leafy greens' quality compared to conventional room cooling methods.

Impact on Leafy Greens' Shelf Life

Vacuum cooling rapidly reduces the temperature of leafy greens by removing heat through the evaporation of water, significantly extending shelf life by slowing down respiration and microbial growth. Room cooling cools produce more slowly, leading to higher respiration rates and faster degradation of leaf quality. Studies show vacuum cooling can extend the shelf life of leafy greens by up to 50% compared to room cooling.

Quality Preservation: Texture, Color, and Nutrients Compared

Vacuum cooling rapidly lowers the temperature of leafy greens, effectively preserving crisp texture, vibrant color, and essential nutrients by minimizing enzymatic activity and microbial growth. In contrast, room cooling is slower and often leads to higher moisture loss, resulting in wilting, discoloration, and nutrient degradation. Studies show vacuum cooling extends shelf life and maintains post-harvest quality significantly better than traditional room cooling methods.

Energy Consumption and Operational Costs

Vacuum cooling of leafy greens significantly reduces energy consumption compared to room cooling by rapidly lowering temperature through water evaporation under reduced pressure, leading to faster cooling rates and extended shelf life. Operational costs decrease as vacuum cooling systems use less electricity and reduce the need for refrigeration equipment running time, minimizing labor and maintenance expenses. Despite higher initial investment, vacuum cooling offers cost-efficiency through energy savings and improved product quality, outperforming traditional room cooling in post-harvest handling.

Suitability for Different Types of Leafy Greens

Vacuum cooling is highly effective for delicate leafy greens such as lettuce and spinach, as it rapidly reduces temperature without causing physical damage, preserving texture and extending shelf life. Room cooling suits hardier greens like kale and collard greens, which tolerate slower, less intensive cooling without compromising quality. Selecting the appropriate cooling method depends on the leafy green's sensitivity to moisture loss and temperature fluctuations.

Implementation Challenges and Infrastructure Needs

Vacuum cooling of leafy greens requires specialized equipment such as vacuum chambers and refrigeration units, posing significant infrastructure costs compared to traditional room cooling methods. Implementation challenges include maintaining consistent temperature and humidity control to prevent moisture loss and quality degradation during vacuum cooling. In contrast, room cooling necessitates large, well-ventilated spaces with controlled airflow but generally involves lower capital investment and simpler maintenance.

Choosing the Right Cooling Method for Your Farm

Vacuum cooling rapidly reduces the temperature of leafy greens by evaporative cooling, preserving freshness and extending shelf life, which is ideal for farms with high volume and tight distribution schedules. Room cooling, relying on ambient air circulation, is less energy-intensive but slower, suitable for smaller farms with local markets where immediate cooling pressure is lower. Selecting the appropriate cooling method depends on factors like crop volume, storage duration, transportation distance, and operational budget to optimize post-harvest quality and minimize losses.

Related Important Terms

Rapid Vacuum Hydro-cooling

Rapid vacuum hydro-cooling significantly reduces the temperature of leafy greens within minutes, preserving freshness and extending shelf life by minimizing microbial growth and enzymatic activity. Compared to traditional room cooling, vacuum hydro-cooling ensures uniform cooling, dehydration prevention, and reduces post-harvest losses effectively in commercial processing.

Controlled Atmosphere Vacuum Cooling

Controlled Atmosphere Vacuum Cooling extends shelf life of leafy greens by rapidly removing field heat under reduced pressure while maintaining optimal oxygen and carbon dioxide levels, thus minimizing moisture loss and microbial growth. This method outperforms traditional room cooling by providing uniform temperature reduction and preserving quality, texture, and nutritional content in post-harvest storage.

Energy-Efficient Vacuum Chambers

Vacuum cooling for leafy greens rapidly reduces temperature by evaporative cooling, significantly lowering energy consumption compared to traditional room cooling methods that rely on ambient air circulation. Energy-efficient vacuum chambers minimize moisture loss and operational costs while preserving freshness, extending shelf life and reducing post-harvest spoilage in leafy produce.

Microbial Load Reduction Vacuum

Vacuum cooling rapidly reduces the temperature of leafy greens, creating an environment less conducive to microbial growth compared to traditional room cooling, which cools produce slowly and allows microbes to proliferate. This accelerated cooling process under vacuum conditions effectively lowers microbial load, extending shelf life and maintaining produce quality.

High-Humidity Room Cooling

High-humidity room cooling maintains optimal moisture levels above 90%, significantly reducing leafy greens' weight loss and tissue dehydration compared to vacuum cooling, which can cause moisture loss due to rapid pressure changes. This method extends shelf life and preserves crispness by minimizing transpiration and maintaining cellular structure without the risk of cold injury associated with vacuum cooling.

Differential Cooling Rate

Vacuum cooling reduces the temperature of leafy greens significantly faster than room cooling by rapidly evaporating water under low pressure, achieving a differential cooling rate that can be up to ten times greater. This accelerated cooling minimizes moisture loss and microbial growth, extending shelf life and preserving post-harvest quality more effectively than traditional room cooling methods.

Moisture Loss Minimization

Vacuum cooling rapidly reduces the temperature of leafy greens by evaporative cooling, significantly minimizing moisture loss compared to room cooling, which relies on passive air circulation and results in higher dehydration rates. Maintaining low moisture loss through vacuum cooling preserves leaf turgidity, extending shelf life and overall quality in post-harvest leafy green management.

Pre-cooling Kinetics

Vacuum cooling rapidly reduces the temperature of leafy greens by evaporative cooling, achieving optimal pre-cooling within minutes, whereas room cooling relies on slower convective heat transfer, taking several hours to reach target temperatures. This accelerated cooling kinetics in vacuum cooling significantly extends shelf life and maintains crispness by minimizing microbial growth and moisture loss compared to traditional room cooling methods.

Chill Injury Threshold (leafy greens)

Vacuum cooling rapidly reduces the temperature of leafy greens below their Chill Injury Threshold, minimizing cellular damage and preserving texture and quality, whereas room cooling leads to slower temperature drops that increase the risk of chilling injury. Maintaining temperatures between 0degC and 5degC during vacuum cooling is critical to avoid membrane dysfunction and enzymatic degradation common in leafy greens cooled in ambient air.

Smart Cooling Data Logging

Vacuum cooling rapidly lowers the temperature of leafy greens by removing heat through water evaporation under reduced pressure, significantly extending shelf life and preserving freshness compared to room cooling, which relies on slower ambient air circulation. Smart cooling data logging systems track temperature, humidity, and pressure metrics in real-time during vacuum cooling, enabling precise control and optimization of post-harvest conditions for improved quality and reduced spoilage.

Vacuum cooling vs Room cooling for leafy greens Infographic

agridif.com

agridif.com