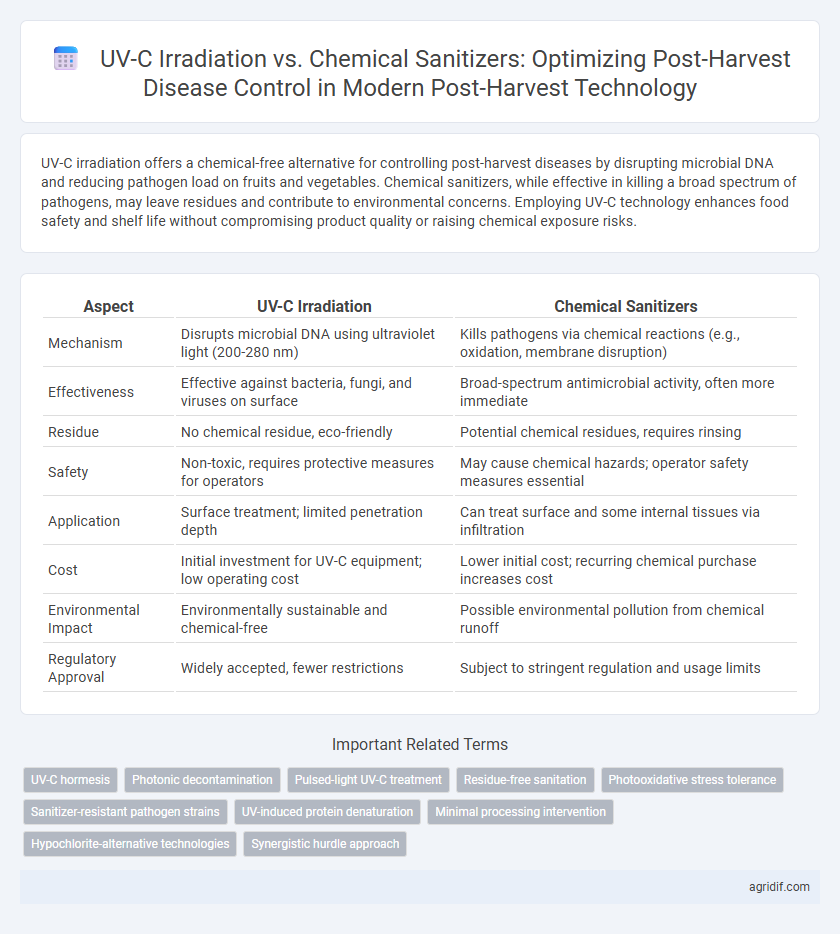

UV-C irradiation offers a chemical-free alternative for controlling post-harvest diseases by disrupting microbial DNA and reducing pathogen load on fruits and vegetables. Chemical sanitizers, while effective in killing a broad spectrum of pathogens, may leave residues and contribute to environmental concerns. Employing UV-C technology enhances food safety and shelf life without compromising product quality or raising chemical exposure risks.

Table of Comparison

| Aspect | UV-C Irradiation | Chemical Sanitizers |

|---|---|---|

| Mechanism | Disrupts microbial DNA using ultraviolet light (200-280 nm) | Kills pathogens via chemical reactions (e.g., oxidation, membrane disruption) |

| Effectiveness | Effective against bacteria, fungi, and viruses on surface | Broad-spectrum antimicrobial activity, often more immediate |

| Residue | No chemical residue, eco-friendly | Potential chemical residues, requires rinsing |

| Safety | Non-toxic, requires protective measures for operators | May cause chemical hazards; operator safety measures essential |

| Application | Surface treatment; limited penetration depth | Can treat surface and some internal tissues via infiltration |

| Cost | Initial investment for UV-C equipment; low operating cost | Lower initial cost; recurring chemical purchase increases cost |

| Environmental Impact | Environmentally sustainable and chemical-free | Possible environmental pollution from chemical runoff |

| Regulatory Approval | Widely accepted, fewer restrictions | Subject to stringent regulation and usage limits |

Introduction to Post-Harvest Disease Control

UV-C irradiation offers a non-chemical approach to post-harvest disease control by disrupting microbial DNA, thereby reducing pathogen load on fresh produce without leaving harmful residues. Chemical sanitizers such as chlorine and quaternary ammonium compounds have been widely used for their rapid antimicrobial effects but may pose risks of chemical residues and environmental impact. Integrating UV-C treatment with or as an alternative to chemical sanitizers enhances the safety and shelf life of horticultural products while addressing consumer demand for minimally processed foods.

Overview of UV-C Irradiation Technology

UV-C irradiation technology utilizes short-wavelength ultraviolet light (200-280 nm) to effectively reduce microbial load and inhibit fungal growth on fresh produce, extending shelf life without chemical residues. This non-thermal, residue-free method disrupts DNA and RNA of pathogens, offering an eco-friendly alternative to traditional chemical sanitizers like chlorine and peracetic acid. Studies demonstrate UV-C treatment's potential to control common post-harvest diseases such as gray mold and blue mold while maintaining produce quality and minimizing environmental impact.

Chemical Sanitizers: Types and Applications

Chemical sanitizers such as chlorine, sodium hypochlorite, and peracetic acid are widely used in post-harvest disease control to reduce microbial loads on fruits and vegetables. These sanitizers effectively inhibit bacterial and fungal growth during storage and transportation, enhancing shelf life and product safety. Application methods include dipping, spraying, and washing to ensure thorough surface sanitization and minimize post-harvest losses.

Mechanisms of Action: UV-C vs Chemical Treatments

UV-C irradiation in post-harvest disease control disrupts microbial DNA and induces plant defense responses by generating reactive oxygen species, leading to reduced pathogen viability. Chemical sanitizers, such as chlorine and hydrogen peroxide, act through oxidative damage and membrane disruption to inactivate pathogens on fruit and vegetable surfaces. UV-C offers a residue-free alternative with potential to enhance natural resistance, while chemical treatments provide immediate antimicrobial efficacy but may pose environmental and health concerns.

Efficacy Against Common Post-Harvest Pathogens

UV-C irradiation effectively reduces microbial load by damaging the DNA of common post-harvest pathogens such as Botrytis cinerea, Penicillium spp., and Colletotrichum spp., thereby limiting decay in fruits and vegetables. Chemical sanitizers, including chlorine and peracetic acid, inactivate pathogens by oxidizing cell components but may cause residues and resistance issues. Comparative studies highlight UV-C as a residue-free alternative with broad-spectrum efficacy, though its penetration and dose optimization remain critical for maximal pathogen control.

Effects on Produce Quality and Shelf Life

UV-C irradiation effectively reduces microbial load on produce surfaces without compromising firmness, color, or nutritional content, thereby extending shelf life by delaying ripening and decay processes. Chemical sanitizers, such as chlorine-based solutions, can control post-harvest diseases but sometimes cause surface damage or chemical residues that may affect produce quality and consumer safety. Studies indicate UV-C treatments offer a safer alternative for maintaining sensory attributes and prolonging the marketability of fruits and vegetables compared to traditional chemical sanitizers.

Environmental Impact and Safety Considerations

UV-C irradiation offers an eco-friendly alternative to chemical sanitizers by reducing the reliance on harmful pesticides and minimizing chemical residues on produce, thereby lowering environmental pollution. Its non-chemical approach eliminates toxic effluents and decreases the risk of developing resistant pathogen strains, promoting sustainable post-harvest disease management. Safety considerations highlight UV-C's controlled exposure requirements to prevent operator hazards, whereas chemical sanitizers pose risks of toxic residue, worker exposure, and potential adverse health effects.

Regulatory Standards and Consumer Acceptance

UV-C irradiation for post-harvest disease control aligns with increasingly stringent regulatory standards due to its residue-free nature, enhancing food safety and environmental compliance. Chemical sanitizers often face stricter restrictions and scrutiny related to permissible residue limits and environmental impact, influencing their regulatory approval and marketability. Consumer acceptance favors UV-C treatments as a non-chemical alternative, promoting perceptions of safer, more natural produce without compromising efficacy in disease control.

Challenges and Limitations of Each Method

UV-C irradiation faces challenges such as limited penetration depth, which restricts its effectiveness on irregular or dense fruit surfaces, and potential damage to sensitive produce causing quality deterioration. Chemical sanitizers present limitations including the development of resistant microbial strains, residue concerns, and environmental contamination from excessive use. Both methods require optimization in dosage and application to balance disease control efficacy with crop safety and consumer health.

Future Prospects and Integrated Approaches

UV-C irradiation presents a promising future prospect for post-harvest disease control due to its capability to reduce microbial load without chemical residues, aligning with increasing consumer demand for safer food preservation methods. Integrating UV-C treatment with low-dose chemical sanitizers can enhance efficacy by targeting diverse pathogens and minimizing sanitizer usage, thereby reducing environmental impact and resistance development. Research on optimizing combined protocols and understanding synergistic effects is crucial for advancing sustainable post-harvest management strategies.

Related Important Terms

UV-C hormesis

UV-C irradiation induces a hormetic response in post-harvest produce, enhancing disease resistance by stimulating natural defense mechanisms while reducing reliance on chemical sanitizers that may leave harmful residues. This hormesis effect optimizes microbial control and prolongs shelf life, offering an eco-friendly alternative for managing post-harvest diseases.

Photonic decontamination

UV-C irradiation offers an effective photonic decontamination method for post-harvest disease control, utilizing germicidal wavelengths to disrupt microbial DNA and reduce pathogen load without chemical residues. Unlike chemical sanitizers, UV-C treatment minimizes environmental impact and residue concerns while maintaining produce quality and shelf life through non-invasive surface sterilization.

Pulsed-light UV-C treatment

Pulsed-light UV-C treatment offers a potent, chemical-free alternative for post-harvest disease control by effectively inactivating a broad spectrum of pathogens through high-intensity, short-duration bursts of ultraviolet light. Unlike traditional chemical sanitizers, pulsed UV-C minimizes residue concerns and environmental impact while enhancing produce shelf life and safety by disrupting microbial DNA and cellular structures.

Residue-free sanitation

UV-C irradiation offers residue-free sanitation by effectively inactivating pathogens on post-harvest produce without leaving chemical residues, making it a safer alternative to traditional chemical sanitizers. This technology reduces the risk of chemical contamination while maintaining fruit quality and extending shelf life through non-thermal pathogen control.

Photooxidative stress tolerance

UV-C irradiation enhances photooxidative stress tolerance in post-harvest fruits by inducing antioxidant enzyme activities, effectively reducing disease incidence without chemical residues. Chemical sanitizers often fail to improve the fruit's innate defense mechanisms, making UV-C a superior alternative for sustainable post-harvest disease control.

Sanitizer-resistant pathogen strains

UV-C irradiation effectively reduces post-harvest disease by damaging microbial DNA and is particularly valuable against sanitizer-resistant pathogen strains that have developed tolerance to chemical treatments. Unlike chemical sanitizers, which often lose efficacy due to resistance mechanisms such as biofilm formation and enzymatic degradation, UV-C provides a non-chemical, residue-free alternative enhancing shelf life and reducing pathogen load without promoting resistance.

UV-induced protein denaturation

UV-C irradiation effectively controls post-harvest diseases by inducing protein denaturation in microbial pathogens, disrupting their cellular functions and preventing spoilage without chemical residues. Unlike traditional chemical sanitizers, UV-C treatment offers a residue-free alternative that reduces pathogen viability while maintaining produce quality and safety.

Minimal processing intervention

UV-C irradiation effectively reduces microbial load on fresh produce with minimal processing intervention, preserving product quality without chemical residues. Unlike chemical sanitizers, UV-C treatment offers a residue-free alternative that enhances shelf life while minimizing environmental impact and consumer health risks.

Hypochlorite-alternative technologies

UV-C irradiation offers a chemical-free alternative to traditional hypochlorite-based sanitizers, effectively reducing post-harvest decay by damaging microbial DNA and inhibiting pathogen growth on fruits and vegetables. This technology minimizes residual chemical risks and environmental impact while maintaining produce quality and extending shelf life compared to conventional chlorine treatments.

Synergistic hurdle approach

UV-C irradiation combined with chemical sanitizers enhances post-harvest disease control by leveraging synergistic hurdle technology, reducing microbial load more effectively than individual treatments. This integrative approach minimizes chemical residues and delays pathogen resistance, improving the safety and shelf life of perishable produce.

UV-C irradiation vs Chemical sanitizers for post-harvest disease control Infographic

agridif.com

agridif.com