Palletization enhances the protection and organization of cereals by reducing contamination and facilitating easier handling during storage and transportation. In contrast, bulk storage offers higher capacity and cost efficiency but increases the risk of pest infestation and uneven aeration. Choosing between palletization and bulk storage depends on factors like storage duration, infrastructure, and post-harvest loss minimization priorities.

Table of Comparison

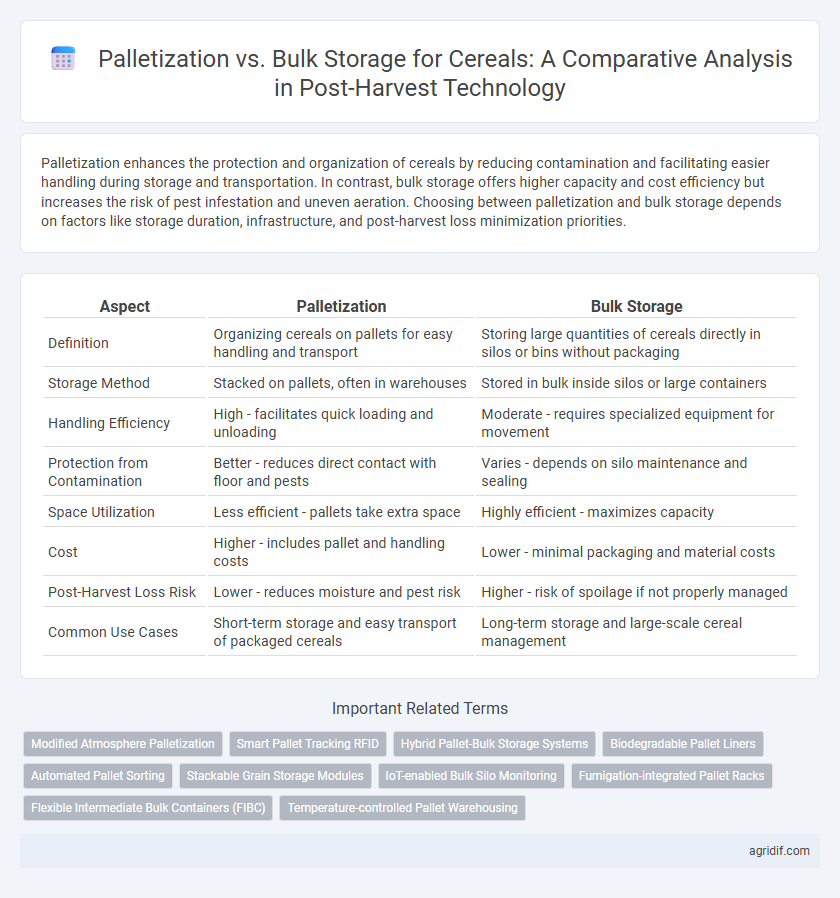

| Aspect | Palletization | Bulk Storage |

|---|---|---|

| Definition | Organizing cereals on pallets for easy handling and transport | Storing large quantities of cereals directly in silos or bins without packaging |

| Storage Method | Stacked on pallets, often in warehouses | Stored in bulk inside silos or large containers |

| Handling Efficiency | High - facilitates quick loading and unloading | Moderate - requires specialized equipment for movement |

| Protection from Contamination | Better - reduces direct contact with floor and pests | Varies - depends on silo maintenance and sealing |

| Space Utilization | Less efficient - pallets take extra space | Highly efficient - maximizes capacity |

| Cost | Higher - includes pallet and handling costs | Lower - minimal packaging and material costs |

| Post-Harvest Loss Risk | Lower - reduces moisture and pest risk | Higher - risk of spoilage if not properly managed |

| Common Use Cases | Short-term storage and easy transport of packaged cereals | Long-term storage and large-scale cereal management |

Overview of Palletization and Bulk Storage in Cereal Post-Harvest Management

Palletization in cereal post-harvest management involves stacking bags or containers on pallets, facilitating easier handling, transportation, and inventory control while maintaining product quality by reducing direct contact with the ground. Bulk storage stores loose grains in large quantities within silos or bins, optimizing space and allowing for better aeration and temperature control to prevent spoilage and pest infestation. Both methods play crucial roles in reducing post-harvest losses, with palletization offering improved logistics efficiency and bulk storage providing scalable preservation solutions.

Key Principles of Palletization for Cereals

Palletization for cereals involves systematic stacking on pallets to enhance aeration, reduce contamination, and facilitate efficient handling and transportation. Key principles include uniform grain packaging to maintain stability, allowing adequate airflow between stacks to minimize moisture buildup, and optimizing pallet size for storage and transit compatibility. This method significantly reduces post-harvest losses by preventing grain spoilage and pest infestation compared to traditional bulk storage.

Advantages of Bulk Storage Systems for Grain

Bulk storage systems for grain offer significant advantages including improved space utilization, which reduces the storage footprint compared to palletization. Enhanced aeration and temperature control in bulk storage minimize spoilage and insect infestation, thereby preserving grain quality for extended periods. Automated handling and monitoring capabilities in bulk storage also increase operational efficiency and reduce labor costs during post-harvest management.

Space Utilization: Palletization vs Bulk Storage

Palletization enhances space utilization by allowing cereals to be stacked vertically and organized efficiently, minimizing floor space requirements. Bulk storage, while suitable for large quantities, often leads to uneven filling and wasted volumes due to the irregular shape of storage structures. Optimizing space through palletization supports better airflow and reduces post-harvest losses compared to the limited spatial efficiency of bulk storage systems.

Impact on Grain Quality and Shelf Life

Palletization enhances grain quality and shelf life by promoting better aeration and reducing moisture accumulation, which minimizes fungal growth and insect infestation. Bulk storage often leads to uneven temperature and moisture distribution, increasing the risk of grain spoilage and quality degradation. Properly managed palletized storage can extend cereal shelf life by maintaining optimal conditions that bulk storage struggles to achieve consistently.

Handling and Transportation Efficiency

Palletization enhances handling and transportation efficiency for cereals by enabling standardized stacking, reducing loading and unloading times, and minimizing product damage during transit. Bulk storage, while suitable for large volumes, often requires specialized equipment and can increase handling complexity and transportation risks due to uneven load distribution. Optimizing palletized cereal shipments supports streamlined logistics, better space utilization, and improved protection throughout the supply chain.

Cost Analysis: Initial Investment and Operational Expenses

Palletization of cereals requires higher initial investment due to costs of pallets, racks, and forklifts, but it enables better inventory management and reduces product damage, lowering operational expenses over time. Bulk storage involves lower upfront costs with simple silos or bins but may lead to higher expenses from increased spoilage, handling inefficiencies, and pest control. Overall, palletization offers long-term cost savings through improved handling efficiency despite larger initial capital outlay, while bulk storage prioritizes minimal initial investment but potentially higher ongoing maintenance and loss costs.

Flexibility in Storage Capacity and Expansion

Palletization offers significant flexibility in storage capacity and expansion due to its modular design, allowing for easy reconfiguration and vertical stacking to maximize warehouse space efficiency. Bulk storage, while capable of handling large volumes, typically requires fixed infrastructure and is less adaptable to varying storage demands or incremental expansion. Therefore, palletization supports scalable operations and dynamic inventory management crucial for post-harvest cereal storage.

Risks of Infestation and Contamination

Palletization in post-harvest cereal storage significantly reduces the risk of infestation and contamination by elevating grains off the ground, preventing moisture absorption and limiting pest access. Bulk storage increases exposure to pests and fungal contamination due to difficulty in monitoring and aerating large grain masses, which can harbor hotspots of moisture and insect activity. Effective pest management and contamination control are more challenging in bulk storage, making palletization a preferred method for preserving grain quality.

Choosing the Right Storage Method for Specific Cereals

Palletization offers enhanced aeration and reduced pest infestation for grains like wheat and barley, ensuring prolonged freshness and quality. Bulk storage is ideal for high-volume cereals such as maize and rice, allowing efficient space utilization and cost-effectiveness. Selecting the appropriate storage method depends on the cereal type, moisture content, and intended storage duration to minimize post-harvest losses effectively.

Related Important Terms

Modified Atmosphere Palletization

Modified Atmosphere Palletization (MAP) enhances cereal storage by reducing oxygen levels around palletized grains, significantly slowing spoilage and pest infestation compared to traditional bulk storage. This technique improves shelf life and quality preservation through controlled gas composition, making it a superior post-harvest technology for cereals.

Smart Pallet Tracking RFID

Smart Pallet Tracking RFID enhances palletization by providing real-time visibility and efficient management of cereal inventory, reducing losses caused by improper handling and storage. Compared to bulk storage, RFID-enabled palletization ensures precise tracking of individual pallet movements, improving supply chain transparency and minimizing post-harvest grain spoilage.

Hybrid Pallet-Bulk Storage Systems

Hybrid pallet-bulk storage systems combine the advantages of palletization, such as improved aeration and easier handling, with the space efficiency of bulk storage, optimizing post-harvest cereal preservation by minimizing grain spoilage and infestation. These systems enhance storage management by facilitating better airflow, temperature control, and quicker inventory turnover compared to traditional bulk or solely palletized methods.

Biodegradable Pallet Liners

Biodegradable pallet liners enhance palletization by preventing contamination and moisture absorption in cereals, ensuring safer storage and reducing environmental impact compared to traditional bulk storage methods. This innovation improves aeration and handling efficiency while facilitating sustainable post-harvest practices in cereal supply chains.

Automated Pallet Sorting

Automated pallet sorting in palletization enhances efficiency by organizing cereal grain bags with precision, reducing manual labor and minimizing post-harvest losses compared to bulk storage. This technology optimizes warehouse space utilization and improves inventory management, ensuring better protection against contamination and spoilage during storage.

Stackable Grain Storage Modules

Stackable grain storage modules offer optimized space utilization and improved aeration compared to traditional bulk storage, enhancing post-harvest grain quality and reducing infestation risks. Palletization facilitates easier handling and transport of cereals, promoting efficient inventory management and minimizing grain damage during storage and movement.

IoT-enabled Bulk Silo Monitoring

IoT-enabled bulk silo monitoring enhances post-harvest technology by providing real-time data on temperature, humidity, and grain quality, significantly reducing losses during bulk storage of cereals. Compared to palletization, bulk storage with IoT integration offers scalable capacity and automated condition control, optimizing shelf life and minimizing labor costs.

Fumigation-integrated Pallet Racks

Fumigation-integrated pallet racks in palletization enhance pest control efficiency by sealing and treating cereals in stacked units, reducing contamination and grain loss compared to traditional bulk storage. This method facilitates uniform fumigant distribution, accelerates aeration, and improves overall post-harvest grain quality preservation.

Flexible Intermediate Bulk Containers (FIBC)

Flexible Intermediate Bulk Containers (FIBC) offer enhanced efficiency in palletization by improving stacking stability and space utilization compared to traditional bulk storage for cereals. These containers reduce product damage, facilitate easier handling, and optimize post-harvest storage and transportation logistics in cereal supply chains.

Temperature-controlled Pallet Warehousing

Temperature-controlled pallet warehousing enhances post-harvest cereal preservation by stabilizing temperature and humidity, reducing pest infestation and mold growth compared to bulk storage. Palletization facilitates improved air circulation and easier inventory management, leading to prolonged grain quality and reduced post-harvest losses.

Palletization vs Bulk storage for cereals Infographic

agridif.com

agridif.com