Infrared drying offers faster moisture removal and better preservation of flavor and color in spices compared to traditional hot air drying. This method penetrates spices more deeply, reducing drying time and minimizing nutrient loss while enhancing product quality. Hot air drying, although widely used, often requires longer exposure times and can cause uneven drying and degradation of volatile compounds in spices.

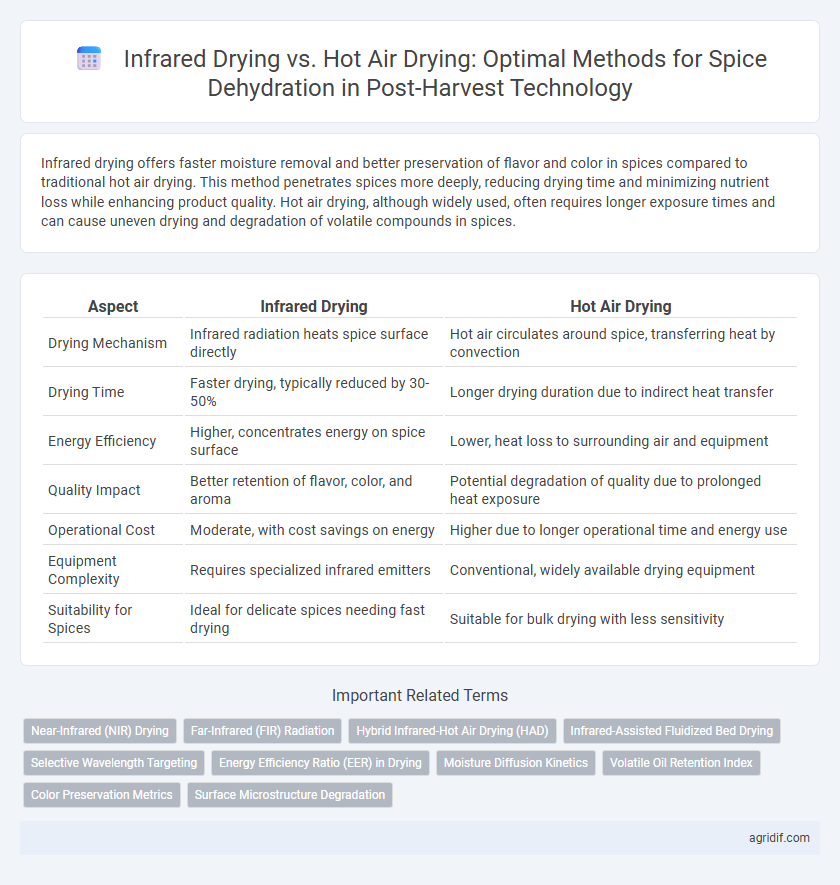

Table of Comparison

| Aspect | Infrared Drying | Hot Air Drying |

|---|---|---|

| Drying Mechanism | Infrared radiation heats spice surface directly | Hot air circulates around spice, transferring heat by convection |

| Drying Time | Faster drying, typically reduced by 30-50% | Longer drying duration due to indirect heat transfer |

| Energy Efficiency | Higher, concentrates energy on spice surface | Lower, heat loss to surrounding air and equipment |

| Quality Impact | Better retention of flavor, color, and aroma | Potential degradation of quality due to prolonged heat exposure |

| Operational Cost | Moderate, with cost savings on energy | Higher due to longer operational time and energy use |

| Equipment Complexity | Requires specialized infrared emitters | Conventional, widely available drying equipment |

| Suitability for Spices | Ideal for delicate spices needing fast drying | Suitable for bulk drying with less sensitivity |

Introduction to Spice Dehydration Technologies

Infrared drying and hot air drying are two prominent technologies used for spice dehydration, each offering distinct advantages in preserving flavor and nutritional content. Infrared drying utilizes electromagnetic radiation to penetrate spice layers, enabling rapid moisture removal with minimal thermal degradation, while hot air drying relies on convection by circulating heated air over spices to evaporate moisture. Comparing energy efficiency, drying time, and product quality highlights infrared drying as a promising alternative to conventional hot air methods in post-harvest spice processing.

Principles of Infrared Drying in Spice Processing

Infrared drying in spice processing relies on electromagnetic radiation to transfer heat directly to the product, enabling rapid moisture removal without significantly raising the surrounding air temperature. This method enhances energy efficiency by converting infrared radiation into thermal energy within the spices, preserving essential oils and bioactive compounds critical for flavor and aroma retention. Unlike hot air drying, infrared drying reduces drying time and minimizes thermal degradation, making it ideal for delicate spice dehydration.

Hot Air Drying: Mechanism and Applications in Spices

Hot air drying relies on the circulation of heated air to remove moisture from spices, effectively reducing water activity and extending shelf life by inhibiting microbial growth. The mechanism involves convective heat transfer, where warm air passes over the spice surface, facilitating evaporation through temperature and humidity control. This method is widely applied to dry spices like chili, turmeric, and black pepper, ensuring color retention, flavor preservation, and improved storage stability.

Comparative Analysis: Drying Time and Efficiency

Infrared drying significantly reduces drying time for spices compared to hot air drying by directly transferring energy to the moisture within the product, resulting in faster dehydration and higher energy efficiency. Hot air drying involves convective heat transfer, leading to longer drying durations and greater energy consumption due to the indirect heating of the spice surface. Studies demonstrate that infrared drying can decrease drying time by up to 50% while improving overall energy utilization, making it a more efficient technology for spice dehydration in post-harvest processes.

Impact on Quality Attributes: Color, Flavor, and Aroma

Infrared drying preserves the vibrant color and natural aroma of spices more effectively than hot air drying by minimizing exposure to high temperatures and oxidation. The rapid and uniform heating in infrared drying enhances flavor retention and reduces nutrient degradation, resulting in superior sensory quality. Hot air drying often leads to color darkening and flavor loss due to prolonged drying times and uneven heat distribution.

Energy Consumption and Cost Considerations

Infrared drying consumes significantly less energy than hot air drying due to its direct heat transfer mechanism, enabling faster moisture removal and reducing drying time for spices. This energy efficiency translates into lower operational costs, making infrared drying a more cost-effective option for spice dehydration in large-scale applications. Although initial equipment investment may be higher, the long-term savings in energy expenditure and improved product quality justify the financial outlay.

Microbial Safety and Shelf Life Enhancement

Infrared drying significantly reduces microbial load in spices by rapidly killing pathogens through high penetration heat, compared to hot air drying which relies on slower convective heat transfer. This accelerated microbial inactivation in infrared drying enhances microbial safety and reduces the risk of post-process contamination. Consequently, spices dried with infrared technology exhibit extended shelf life due to lower initial microbial populations and reduced moisture content, limiting spoilage and maintaining quality during storage.

Environmental Sustainability of Drying Methods

Infrared drying for spice dehydration significantly reduces energy consumption by directly heating the product, leading to lower greenhouse gas emissions compared to conventional hot air drying, which requires prolonged exposure to high temperatures and airflow. Infrared technology minimizes water vapor release, reducing the environmental impact associated with moisture-laden exhaust gases typical of hot air systems. By offering faster drying times and improved energy efficiency, infrared drying enhances the sustainability profile of spice processing operations in the post-harvest supply chain.

Technological Advances and Equipment Requirements

Infrared drying offers rapid moisture removal with uniform heat distribution, reducing drying time and preserving spice quality compared to traditional hot air drying. Technological advances include precise wavelength control and energy-efficient infrared emitters, enabling enhanced dehydration performance and lower operational costs. Equipment requirements for infrared systems involve specialized emitters and reflective chambers, contrasting with the larger, ventilation-intensive apparatus needed for hot air dryers.

Practical Recommendations for Spice Producers

Infrared drying offers faster moisture removal and better retention of volatile oils compared to conventional hot air drying, making it ideal for preserving spice aroma and flavor. Spice producers should optimize parameters like infrared intensity and drying duration to prevent overheating and degradation of sensitive compounds. Integrating infrared drying with controlled air circulation can enhance efficiency and product quality, reducing energy consumption in large-scale spice dehydration processes.

Related Important Terms

Near-Infrared (NIR) Drying

Near-Infrared (NIR) drying accelerates spice dehydration by directly penetrating the cellular structure, enhancing moisture removal efficiency compared to conventional hot air drying that relies on surface heat transfer. This results in reduced drying time, improved retention of volatile oils, and preservation of sensory quality in spices such as cumin and coriander.

Far-Infrared (FIR) Radiation

Far-Infrared (FIR) radiation in spice dehydration significantly enhances drying efficiency by penetrating deeper into the spice material, ensuring uniform moisture removal without compromising aroma or bioactive compounds. Compared to conventional hot air drying, FIR drying reduces processing time and energy consumption while preserving the nutritional and sensory qualities critical for high-quality spice production.

Hybrid Infrared-Hot Air Drying (HAD)

Hybrid Infrared-Hot Air Drying (HAD) combines the rapid surface heating of infrared radiation with the uniform moisture removal of hot air, enhancing drying efficiency and preserving the essential oils and flavor compounds in spices. This method reduces drying time and energy consumption compared to traditional hot air drying alone, offering improved product quality and extended shelf life in post-harvest spice dehydration.

Infrared-Assisted Fluidized Bed Drying

Infrared-assisted fluidized bed drying enhances spice dehydration by combining rapid, uniform heat transfer from infrared radiation with efficient moisture removal through fluidized bed airflow, resulting in higher drying rates and better preservation of aroma and color compared to traditional hot air drying. This hybrid method reduces drying time by up to 40% and improves energy efficiency while maintaining the quality attributes critical for spices like turmeric and black pepper.

Selective Wavelength Targeting

Infrared drying in spice dehydration utilizes selective wavelength targeting to penetrate and heat the product efficiently, resulting in faster moisture removal and better preservation of volatile compounds compared to hot air drying. This targeted energy absorption reduces drying time and energy consumption while maintaining superior spice quality and aroma retention.

Energy Efficiency Ratio (EER) in Drying

Infrared drying exhibits a higher Energy Efficiency Ratio (EER) compared to hot air drying in spice dehydration, allowing faster moisture removal with lower energy consumption. This enhanced EER results from direct energy transfer to the spice surface, minimizing heat loss and reducing drying time significantly.

Moisture Diffusion Kinetics

Infrared drying accelerates moisture diffusion kinetics in spice dehydration by providing rapid surface heating, which enhances the internal moisture migration rate compared to hot air drying. Hot air drying relies on convective heat transfer, resulting in slower moisture diffusion and longer drying times due to lower heat penetration efficiency.

Volatile Oil Retention Index

Infrared drying demonstrates a higher Volatile Oil Retention Index compared to hot air drying, preserving more essential oils critical for spice flavor and aroma. This enhanced retention results from infrared's rapid heating mechanism, which minimizes thermal degradation during spice dehydration.

Color Preservation Metrics

Infrared drying retains higher levels of chlorophyll and carotenoids in spices, resulting in superior color preservation with minimal enzymatic browning compared to hot air drying. Spectrophotometric analysis reveals infrared-treated spices maintain a more vibrant L*a*b* color profile, indicating enhanced visual quality and consumer appeal.

Surface Microstructure Degradation

Infrared drying preserves the surface microstructure of spices better than hot air drying by minimizing cellular damage and maintaining cell wall integrity. Hot air drying causes more severe surface microstructure degradation due to prolonged exposure to high temperatures, leading to reduced quality and flavor retention.

Infrared Drying vs Hot Air Drying for spice dehydration Infographic

agridif.com

agridif.com