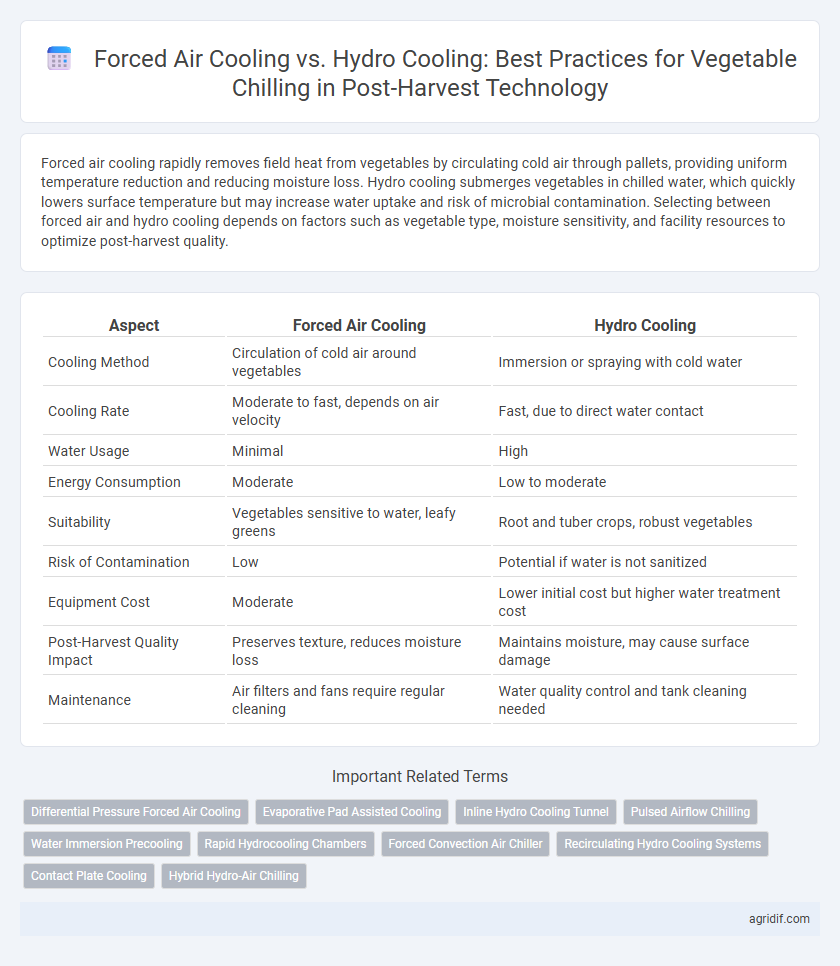

Forced air cooling rapidly removes field heat from vegetables by circulating cold air through pallets, providing uniform temperature reduction and reducing moisture loss. Hydro cooling submerges vegetables in chilled water, which quickly lowers surface temperature but may increase water uptake and risk of microbial contamination. Selecting between forced air and hydro cooling depends on factors such as vegetable type, moisture sensitivity, and facility resources to optimize post-harvest quality.

Table of Comparison

| Aspect | Forced Air Cooling | Hydro Cooling |

|---|---|---|

| Cooling Method | Circulation of cold air around vegetables | Immersion or spraying with cold water |

| Cooling Rate | Moderate to fast, depends on air velocity | Fast, due to direct water contact |

| Water Usage | Minimal | High |

| Energy Consumption | Moderate | Low to moderate |

| Suitability | Vegetables sensitive to water, leafy greens | Root and tuber crops, robust vegetables |

| Risk of Contamination | Low | Potential if water is not sanitized |

| Equipment Cost | Moderate | Lower initial cost but higher water treatment cost |

| Post-Harvest Quality Impact | Preserves texture, reduces moisture loss | Maintains moisture, may cause surface damage |

| Maintenance | Air filters and fans require regular cleaning | Water quality control and tank cleaning needed |

Introduction to Post-Harvest Vegetable Cooling

Post-harvest vegetable cooling is essential to slow metabolic activity and reduce spoilage, extending shelf life and maintaining quality. Forced air cooling rapidly removes field heat by circulating cold air uniformly around vegetables, ideal for bulky or densely packed produce. Hydro cooling, using chilled water immersion, provides faster and more efficient cooling for heat-sensitive vegetables, while also cleaning the produce during the process.

Overview of Forced Air Cooling

Forced air cooling rapidly reduces the temperature of vegetables by circulating chilled air uniformly through pallets or bins, preventing moisture loss and maintaining product quality. This method is highly energy-efficient and widely adopted for root crops, leafy greens, and other produce that require consistent cooling to extend shelf life. Forced air systems are customizable for different packing configurations, ensuring optimal airflow and faster cooling times compared to hydro cooling.

Understanding Hydro Cooling Methods

Hydro cooling involves immersing vegetables in cold water or using a continuous flow of chilled water to absorb field heat rapidly, which significantly reduces the temperature within minutes. This method ensures uniform cooling, maintains high humidity levels, and minimizes weight loss, making it highly effective for leafy greens and delicate produce. Compared to forced air cooling, hydro cooling offers faster temperature reduction but requires careful water management to prevent microbial contamination and waterborne diseases.

Key Advantages of Forced Air Cooling

Forced Air Cooling provides rapid and uniform temperature reduction by circulating chilled air efficiently through the vegetable pallets, minimizing spoilage and extending shelf life. It offers greater flexibility for mixed loads and varied produce types due to adjustable airflow patterns. This method uses less water compared to Hydro Cooling, reducing the risk of cross-contamination and lowering operational costs.

Notable Benefits of Hydro Cooling

Hydro cooling rapidly reduces produce temperature by immersing vegetables in cold water, enhancing moisture retention and minimizing weight loss compared to forced air cooling. This method improves shelf life and maintains product quality by efficiently removing field heat through direct contact. Hydro cooling also reduces dehydration and shriveling, making it ideal for high-water-content vegetables like leafy greens and broccoli.

Comparative Energy Efficiency of Cooling Methods

Forced air cooling utilizes high-velocity chilled air circulated through produce, consuming less energy due to targeted cooling and reduced water use. Hydro cooling involves immersion or spraying with cold water, leading to higher energy and water consumption driven by water pumping and chilling requirements. Energy efficiency analysis favors forced air cooling for its lower operational costs and environmental impact in vegetable chilling processes.

Impact on Vegetable Shelf Life and Quality

Forced air cooling rapidly removes field heat by circulating cold air around vegetables, significantly extending shelf life while maintaining firmness and reducing moisture loss. Hydro cooling, involving immersion in chilled water, quickly lowers temperature but may increase water absorption, leading to surface discoloration and potential microbial growth that can compromise vegetable quality. Selecting the appropriate cooling method depends on vegetable type, desired shelf life extension, and maintaining overall post-harvest quality.

Cost Considerations: Forced Air vs Hydro Cooling

Forced air cooling typically incurs lower initial equipment costs compared to hydro cooling, making it more accessible for small to medium-scale operations. Hydro cooling requires substantial water use and infrastructure, increasing operational expenses and limiting its feasibility in regions with water scarcity. Energy consumption varies as well, with forced air systems relying primarily on fans, whereas hydro cooling demands pumps and water treatment, impacting overall cost efficiency depending on local utility prices.

Food Safety and Sanitation Aspects

Forced air cooling utilizes high-velocity cold air to rapidly reduce vegetable temperature, minimizing microbial growth by maintaining low humidity that discourages pathogen proliferation. Hydro cooling involves immersing vegetables in chilled water, which can pose food safety risks if water quality and sanitation protocols are not meticulously maintained, potentially leading to cross-contamination. Effective sanitation measures such as regular water treatment and equipment cleaning are critical in hydro cooling to prevent microbial contamination, whereas forced air cooling requires less intensive sanitation but demands proper airflow management to ensure uniform cooling and avoid spoilage.

Choosing the Ideal Cooling Method for Vegetables

Forced air cooling offers rapid temperature reduction by circulating cold air uniformly around vegetables, making it ideal for produce with high respiration rates such as lettuce and spinach. Hydro cooling uses cold water immersion to quickly lower product temperature and is especially effective for dense, hard-to-cool vegetables like carrots and broccoli due to direct contact cooling. Selecting the ideal cooling method depends on factors like vegetable type, moisture sensitivity, cooling speed requirements, and energy efficiency to optimize post-harvest quality and shelf life.

Related Important Terms

Differential Pressure Forced Air Cooling

Differential Pressure Forced Air Cooling enhances post-harvest vegetable chilling by uniformly distributing cold air through produce, reducing cooling time compared to Hydro Cooling which relies on water immersion and may cause moisture-related quality issues. This method maintains better texture and shelf life by preventing excessive moisture uptake and minimizing microbial growth associated with water-based cooling systems.

Evaporative Pad Assisted Cooling

Forced air cooling rapidly lowers the temperature of vegetables by circulating cold air through packed produce and is highly effective for uniform cooling, whereas hydro cooling uses cold water immersion for faster chilling but risks waterborne contamination. Evaporative pad assisted cooling combines forced air circulation with moisture-retentive pads, enhancing evaporative cooling efficiency by reducing produce temperature through evaporative heat loss, improving shelf life and maintaining vegetable quality under controlled humidity.

Inline Hydro Cooling Tunnel

Inline Hydro Cooling Tunnels provide efficient and uniform cooling for vegetables by rapidly removing field heat through direct water contact, which significantly reduces respiration rates and extends shelf life. Compared to Forced Air Cooling, these tunnels minimize moisture loss and surface dehydration, ensuring better product quality and longer marketability in post-harvest handling.

Pulsed Airflow Chilling

Pulsed airflow chilling combines the efficiency of forced air cooling with intermittent airflow patterns to enhance heat removal from vegetables, reducing cooling time and minimizing moisture loss compared to continuous forced air methods. This technique offers faster temperature reduction than hydro cooling while avoiding excess water exposure, thereby maintaining product quality and extending shelf life.

Water Immersion Precooling

Water immersion precooling, a type of hydro cooling, rapidly reduces the temperature of vegetables by submerging them in chilled water, effectively removing field heat and minimizing moisture loss. Compared to forced air cooling, water immersion offers superior cooling rates for high-density crops, but it requires stringent water quality management to prevent cross-contamination and prolong shelf life.

Rapid Hydrocooling Chambers

Rapid hydrocooling chambers provide efficient and uniform cooling by circulating chilled water directly over vegetables, rapidly reducing field heat compared to forced air cooling, which relies on cold air circulation and typically achieves slower temperature drops. Hydro cooling offers advantages in minimizing weight loss and preserving post-harvest quality, especially for high-respiration-rate vegetables, while forced air cooling is more energy-efficient and less water-intensive.

Forced Convection Air Chiller

Forced Convection Air Chillers utilize high-velocity air circulation to rapidly reduce the temperature of vegetables, enhancing shelf life and maintaining quality by minimizing moisture loss and microbial growth. Compared to Hydro Cooling, this method avoids excess water usage and potential contamination risks, making it more energy-efficient and sustainable for post-harvest vegetable chilling.

Recirculating Hydro Cooling Systems

Recirculating hydro cooling systems offer superior post-harvest vegetable chilling by efficiently maintaining cold water temperatures while reducing water usage compared to traditional forced air cooling methods. These systems enhance heat transfer rates through direct contact, minimizing cooling time and preserving produce freshness and shelf life.

Contact Plate Cooling

Forced air cooling rapidly removes field heat by circulating cold air around vegetables, enhancing uniform chilling but may cause surface dehydration; hydro cooling submerges produce in cold water, providing quick heat removal and reducing water loss, yet risks cross-contamination. Contact plate cooling offers efficient uniform temperature reduction by placing vegetables in direct contact with chilled metal plates, minimizing water usage and surface damage typical in forced air and hydro cooling methods.

Hybrid Hydro-Air Chilling

Hybrid hydro-air chilling combines the rapid surface cooling of forced air with the efficient conductive cooling of hydro cooling, significantly reducing vegetable internal temperatures within minutes. This method enhances shelf life and maintains quality by optimizing temperature uniformity and minimizing moisture loss compared to using either cooling technique alone.

Forced Air Cooling vs Hydro Cooling for vegetable chilling Infographic

agridif.com

agridif.com