Cold chain logistics ensures temperature-controlled environments that preserve the quality and extend the shelf life of perishable goods during transport, minimizing spoilage and waste. Ambient storage, while cost-effective, exposes products to fluctuating temperatures that can accelerate deterioration and compromise safety. Prioritizing cold chain solutions is essential for maintaining freshness and reducing economic losses in post-harvest technology.

Table of Comparison

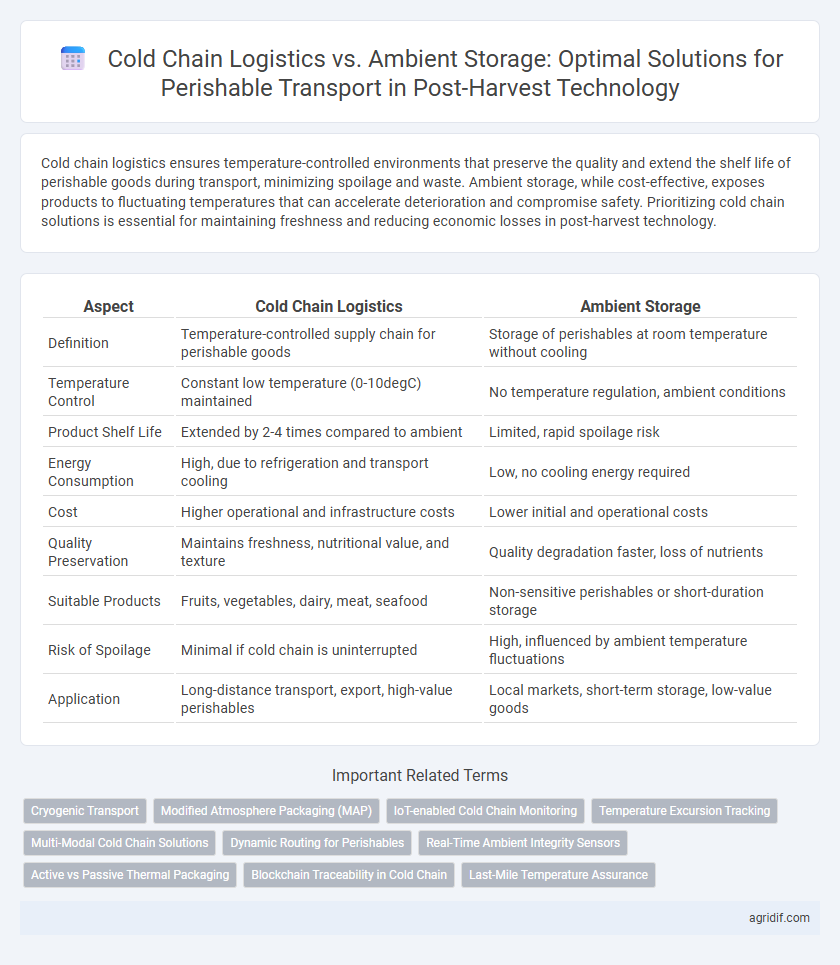

| Aspect | Cold Chain Logistics | Ambient Storage |

|---|---|---|

| Definition | Temperature-controlled supply chain for perishable goods | Storage of perishables at room temperature without cooling |

| Temperature Control | Constant low temperature (0-10degC) maintained | No temperature regulation, ambient conditions |

| Product Shelf Life | Extended by 2-4 times compared to ambient | Limited, rapid spoilage risk |

| Energy Consumption | High, due to refrigeration and transport cooling | Low, no cooling energy required |

| Cost | Higher operational and infrastructure costs | Lower initial and operational costs |

| Quality Preservation | Maintains freshness, nutritional value, and texture | Quality degradation faster, loss of nutrients |

| Suitable Products | Fruits, vegetables, dairy, meat, seafood | Non-sensitive perishables or short-duration storage |

| Risk of Spoilage | Minimal if cold chain is uninterrupted | High, influenced by ambient temperature fluctuations |

| Application | Long-distance transport, export, high-value perishables | Local markets, short-term storage, low-value goods |

Introduction to Perishable Transport in Agriculture

Cold chain logistics ensures the maintenance of optimal low temperatures during the transportation of perishable agricultural products, significantly extending shelf life and reducing spoilage. Ambient storage exposes produce to variable temperatures, increasing the risk of microbial growth and quality degradation. Efficient cold chain systems integrate refrigeration, insulated packaging, and temperature monitoring, crucial for preserving freshness in fruits, vegetables, dairy, and seafood throughout the supply chain.

Defining Cold Chain Logistics and Ambient Storage

Cold chain logistics refers to the temperature-controlled supply chain that ensures perishable goods are preserved from harvest through transportation and storage by maintaining a consistent low temperature, typically between 0degC and 8degC. Ambient storage involves keeping perishable products at uncontrolled room temperatures, which can range from 15degC to 30degC, often leading to faster spoilage and reduced shelf life. Effective cold chain logistics significantly reduce microbial growth and enzymatic activity compared to ambient storage, enhancing product quality and extending market reach.

Key Differences: Cold Chain vs Ambient Storage

Cold chain logistics involves maintaining a controlled temperature environment, typically between 0degC and 8degC, to preserve the freshness and quality of perishable goods during transport and storage. In contrast, ambient storage allows perishable products to be stored and transported at natural or room temperatures, which can vary widely and often reduce shelf life. Cold chain systems reduce spoilage and microbial growth, ensuring extended shelf life and product safety, whereas ambient storage is cost-effective but increases the risk of quality degradation and food loss.

Temperature Control and Its Impact on Shelf Life

Cold chain logistics maintains precise temperature control between 0degC and 4degC, significantly extending the shelf life of perishable goods by slowing microbial growth and enzymatic activity. Ambient storage exposes products to fluctuating temperatures, accelerating spoilage and reducing freshness within days. The superior temperature stability of cold chain systems reduces post-harvest losses and preserves nutritional quality throughout transport and storage.

Cost Analysis: Which Method is More Economical?

Cold chain logistics involves refrigerated transport and storage, incurring higher energy and equipment costs compared to ambient storage, which relies on natural temperature conditions but risks greater spoilage. Cost analysis shows cold chain reduces post-harvest losses significantly, improving overall economic efficiency despite initial expenses. Ambient storage presents lower upfront costs but leads to higher wastage and quality degradation, often resulting in increased total economic loss for perishable goods transport.

Quality Preservation: Nutritional and Visual Aspects

Cold chain logistics significantly enhances quality preservation of perishables by maintaining consistent low temperatures that retard microbial growth and enzymatic reactions, thus preserving nutritional content and visual appeal. Ambient storage, subject to temperature fluctuations, often accelerates spoilage, leading to nutrient degradation and discoloration in fresh produce. Implementing cold chain systems ensures extended shelf life and superior retention of color, texture, and vitamins compared to ambient storage methods.

Infrastructure Requirements and Technological Investments

Cold chain logistics demands advanced refrigeration systems, insulated packaging, and real-time monitoring technologies to maintain optimal temperatures during perishable transport. Infrastructure requirements include climate-controlled warehouses, refrigerated transport vehicles, and energy-efficient cooling units, leading to higher initial technological investments compared to ambient storage. In contrast, ambient storage relies on simpler facilities with minimal temperature control, reducing capital expenditure but increasing the risk of product degradation and food loss.

Sustainability and Environmental Considerations

Cold chain logistics significantly reduce spoilage of perishable goods by maintaining consistent low temperatures, which conserves resources and minimizes food waste, positively impacting environmental sustainability. In contrast, ambient storage often leads to higher spoilage rates, increasing the carbon footprint due to frequent replacements and inefficient resource use. Investing in energy-efficient refrigeration technologies and renewable energy sources for cold chain systems enhances sustainability by lowering greenhouse gas emissions throughout the post-harvest supply chain.

Challenges and Limitations of Each Storage Method

Cold chain logistics ensures optimal temperature control to preserve perishable goods, but faces challenges such as high energy consumption, infrastructure costs, and vulnerability to temperature fluctuations during transit. Ambient storage offers cost-effective and energy-efficient warehousing but is limited by shorter shelf life, increased risk of microbial growth, and susceptibility to environmental variations. Both methods require careful management to balance preservation quality, operational expenses, and supply chain reliability.

Future Trends and Innovations in Perishable Logistics

Innovations in cold chain logistics for perishable transport emphasize real-time temperature monitoring with IoT-enabled sensors, ensuring optimal freshness and reducing spoilage. Advanced phase change materials (PCMs) and smart packaging solutions enhance thermal regulation during transit, outperforming traditional ambient storage. Future trends indicate increasing integration of AI-driven predictive analytics to optimize route planning and minimize delays, revolutionizing perishable supply chain efficiency.

Related Important Terms

Cryogenic Transport

Cryogenic transport in post-harvest technology offers superior preservation of perishable goods by maintaining ultra-low temperatures below -150degC, drastically reducing metabolic rates and microbial growth compared to ambient storage conditions. This cold chain logistics method ensures extended shelf life and better quality retention for fruits, vegetables, and flowers during transit, minimizing spoilage and economic losses.

Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) enhances cold chain logistics by controlling oxygen, carbon dioxide, and nitrogen levels to extend the shelf life of perishable goods during transport. In contrast to ambient storage, MAP significantly reduces respiration rates and microbial growth, ensuring improved freshness and reduced spoilage in perishable food products.

IoT-enabled Cold Chain Monitoring

IoT-enabled cold chain monitoring significantly enhances perishable transport by providing real-time temperature and humidity data, minimizing spoilage and extending shelf life compared to ambient storage. This technology ensures strict compliance with cold chain protocols, reducing waste and maintaining product quality throughout the supply chain.

Temperature Excursion Tracking

Cold chain logistics ensures continuous temperature control during perishable transport, minimizing spoilage risks by detecting and responding to temperature excursions in real-time through advanced tracking technologies. Ambient storage lacks such precise monitoring, increasing the likelihood of temperature fluctuations that compromise product quality and safety.

Multi-Modal Cold Chain Solutions

Multi-modal cold chain solutions enhance the transport of perishables by integrating refrigerated trucking, rail, and air freight, ensuring consistent temperature control and reducing spoilage rates by up to 30%. These advanced logistics outperform ambient storage by maintaining optimal conditions throughout the supply chain, thereby extending shelf life and preserving quality in perishable goods like fruits, vegetables, dairy, and seafood.

Dynamic Routing for Perishables

Dynamic routing for perishables in cold chain logistics ensures temperature-controlled environments throughout transport, significantly reducing spoilage rates compared to ambient storage. Implementing real-time tracking and adaptive route optimization enhances delivery efficiency and maintains product quality by minimizing transit time and exposure to unfavorable conditions.

Real-Time Ambient Integrity Sensors

Cold Chain Logistics employs temperature-controlled environments supported by Real-Time Ambient Integrity Sensors to continuously monitor and ensure optimal conditions for perishable goods during transport, significantly reducing spoilage rates. In contrast, Ambient Storage relies on external factors without real-time condition monitoring, increasing the risk of quality degradation and shortened shelf life for sensitive products.

Active vs Passive Thermal Packaging

Active thermal packaging in cold chain logistics utilizes powered refrigeration systems to maintain precise temperature control for perishable goods, ensuring extended freshness and reduced spoilage during transport. Passive thermal packaging relies on insulating materials and phase change materials (PCMs) to stabilize temperatures without external power, offering cost-effective and energy-efficient solutions primarily suited for short-duration ambient storage.

Blockchain Traceability in Cold Chain

Cold chain logistics ensures optimal temperature control for perishable goods during transport, significantly reducing spoilage and extending shelf life compared to ambient storage. Integrating blockchain traceability enhances transparency and accountability by providing immutable records of temperature data and handling conditions across the cold supply chain.

Last-Mile Temperature Assurance

Cold chain logistics ensures precise temperature control from distribution centers to the consumer, minimizing spoilage and maintaining freshness in perishable transport. Ambient storage lacks temperature regulation during last-mile delivery, increasing the risk of microbial growth and quality degradation for sensitive products.

Cold Chain Logistics vs Ambient Storage for perishable transport Infographic

agridif.com

agridif.com