Water immersion cooling rapidly reduces the temperature of berries by submerging them in cold water, which minimizes respiration rates and extends shelf life effectively. Air blast cooling uses forced cold air circulation around the berries, providing gentle cooling that preserves texture and reduces moisture loss. Choosing between these methods depends on factors like berry type, water availability, and desired cooling speed, with water immersion offering faster cooling and air blast providing better control over moisture retention.

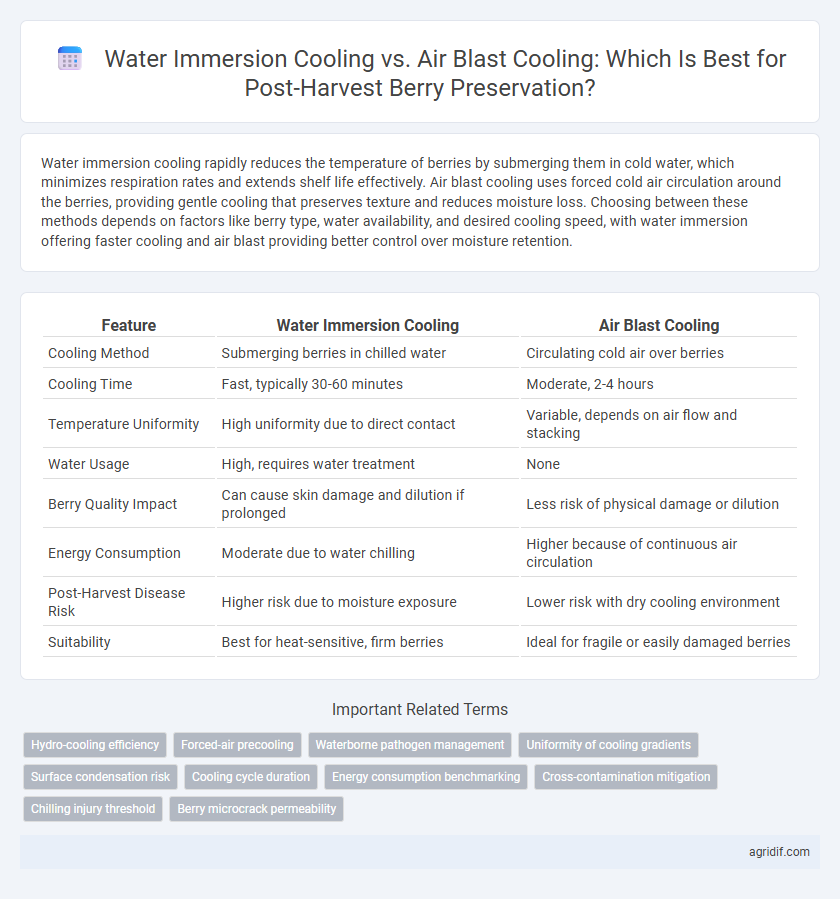

Table of Comparison

| Feature | Water Immersion Cooling | Air Blast Cooling |

|---|---|---|

| Cooling Method | Submerging berries in chilled water | Circulating cold air over berries |

| Cooling Time | Fast, typically 30-60 minutes | Moderate, 2-4 hours |

| Temperature Uniformity | High uniformity due to direct contact | Variable, depends on air flow and stacking |

| Water Usage | High, requires water treatment | None |

| Berry Quality Impact | Can cause skin damage and dilution if prolonged | Less risk of physical damage or dilution |

| Energy Consumption | Moderate due to water chilling | Higher because of continuous air circulation |

| Post-Harvest Disease Risk | Higher risk due to moisture exposure | Lower risk with dry cooling environment |

| Suitability | Best for heat-sensitive, firm berries | Ideal for fragile or easily damaged berries |

Introduction to Post-Harvest Cooling in Berry Production

Post-harvest cooling plays a crucial role in maintaining berry quality by rapidly removing field heat to extend shelf life and reduce microbial spoilage. Water immersion cooling provides uniform temperature reduction and can enhance hydration, but may pose risks of cross-contamination if not properly managed. Air blast cooling offers faster cooling rates and minimizes moisture-related issues, making it effective for preserving berry firmness and preventing decay during storage and transportation.

Principles of Water Immersion Cooling

Water immersion cooling rapidly lowers the temperature of berries by submerging them in chilled water, leveraging direct heat transfer through conduction and convection. This method ensures uniform cooling and reduces field heat quickly, minimizing respiration rates and slowing microbial growth. Optimal water temperature and flow are crucial to prevent flavor dilution and maintain berry quality during post-harvest handling.

Mechanisms of Air Blast Cooling

Air blast cooling for berries relies on high-velocity fans to circulate chilled air uniformly around the fruit, rapidly removing field heat through forced convection. This mechanism accelerates heat transfer from berry surfaces and internal tissues to the cooler air, preserving firmness and extending shelf life by slowing metabolic processes. Compared to water immersion cooling, air blast cooling minimizes moisture-related quality issues such as mold growth and surface pitting while maintaining optimal post-harvest quality.

Comparative Cooling Rates: Water vs. Air

Water immersion cooling offers significantly faster cooling rates for berries compared to air blast cooling, reducing berry temperature by several degrees within minutes due to direct water contact and high heat transfer coefficients. Air blast cooling relies on forced cold air circulation, which is less efficient, often requiring longer times to achieve target temperatures and risking uneven cooling and moisture loss. The superior thermal conductivity of water enhances rapid heat extraction, making water immersion cooling more effective for preserving berry freshness and extending shelf life.

Impact on Berry Quality and Shelf Life

Water immersion cooling rapidly lowers the temperature of berries, reducing respiration rates and delaying spoilage, which helps maintain firmness, color, and overall quality. Air blast cooling offers gentle, uniform cooling without risk of water damage or microbial contamination, preserving surface integrity and reducing decay. Comparatively, water immersion is faster but may increase moisture-related issues, while air blast cooling extends shelf life by minimizing mechanical and microbial stress.

Microbial Risks and Food Safety Considerations

Water immersion cooling effectively reduces berry temperature rapidly but may increase microbial risks due to potential cross-contamination and waterborne pathogens. Air blast cooling minimizes direct contact with moisture, lowering the chance of microbial growth and spoilage. Implementing strict water treatment protocols in immersion systems is crucial to maintaining food safety standards in post-harvest berry handling.

Energy Efficiency and Operational Costs

Water immersion cooling for berries offers superior energy efficiency by rapidly reducing fruit temperature using minimal energy compared to air blast cooling systems. Operational costs are typically lower with water immersion due to decreased energy consumption and shorter cooling times, though water management and sanitation expenses must be considered. Air blast cooling, while more widely applicable, generally incurs higher energy usage and increased operational costs due to prolonged run times and less efficient heat transfer.

Packaging Compatibility and Logistics

Water immersion cooling for berries enhances packaging compatibility by reducing heat rapidly without risking moisture damage when using waterproof containers, making it ideal for watertight packaging systems. Air blast cooling offers broader compatibility with various packaging types, including ventilated trays and clamshells, facilitating easier handling and stacking during transport. Logistic efficiency improves with water immersion cooling through faster cooling cycles, while air blast cooling supports continuous airflow, prolonging berry freshness during extended distribution.

Sustainability and Environmental Impact

Water immersion cooling for berries offers rapid temperature reduction, reducing spoilage and minimizing water usage through recirculation systems, but risks of water contamination and high energy requirements for pumping remain significant. Air blast cooling uses forced chilled air to cool berries, consuming less water and reducing wastewater generation, thereby lowering environmental impact despite longer cooling times and higher electricity usage. Choosing between these methods hinges on balancing water conservation efforts against energy consumption and potential environmental hazards associated with each cooling technology in post-harvest berry management.

Choosing the Optimal Cooling Method for Berries

Water immersion cooling rapidly reduces the temperature of berries by submerging them in chilled water, effectively minimizing respiration rates and preserving firmness, but may increase the risk of microbial contamination if not properly managed. Air blast cooling uses cold, forced air to uniformly lower berry temperatures with reduced moisture exposure and contamination risk, although it requires longer cooling times compared to water immersion. Selecting the optimal cooling method depends on factors such as berry variety, post-harvest handling facilities, and desired shelf life, with water immersion favored for speed and air blast preferred for maintaining surface quality.

Related Important Terms

Hydro-cooling efficiency

Water immersion cooling significantly enhances hydro-cooling efficiency for berries by rapidly reducing surface temperature through direct water contact, resulting in uniform cooling and minimizing respiration rates. This method outperforms air blast cooling by accelerating heat removal, maintaining berry quality, and extending post-harvest shelf life.

Forced-air precooling

Forced-air precooling is widely recognized as the most efficient post-harvest cooling method for berries due to its ability to rapidly reduce field heat and maintain humidity, minimizing moisture loss and decay. Compared to water immersion cooling, forced-air precooling prevents excess water contact, reducing the risk of microbial growth and extending the shelf life of delicate berries.

Waterborne pathogen management

Water immersion cooling rapidly lowers berry temperature but increases the risk of waterborne pathogen spread, necessitating strict water sanitation and anti-microbial treatments; air blast cooling, though slower, minimizes direct water contact and reduces pathogen contamination. Effective post-harvest management combines optimized cooling methods with pathogen control strategies to maintain berry quality and safety.

Uniformity of cooling gradients

Water immersion cooling provides more uniform cooling gradients for berries by rapidly and evenly lowering fruit temperature through direct contact with chilled water, reducing localized heat spots and minimizing temperature disparities. Air blast cooling relies on forced cold air circulation which often results in less consistent cooling due to variable air velocity and airflow distribution around irregularly shaped berries, leading to uneven temperature gradients.

Surface condensation risk

Water immersion cooling rapidly lowers berry temperature but increases the risk of surface condensation, promoting fungal growth and spoilage. Air blast cooling offers gentler cooling with minimal condensation, preserving berry quality and extending shelf life.

Cooling cycle duration

Water immersion cooling significantly reduces the cooling cycle duration for berries by rapidly lowering field heat through direct contact with chilled water, often completing the process within 15 to 30 minutes. Air blast cooling, relying on cold air circulation, typically requires longer durations of 1 to 3 hours to achieve similar temperature reductions due to slower heat transfer rates.

Energy consumption benchmarking

Water immersion cooling for berries demonstrates significantly lower energy consumption compared to air blast cooling, as it enables rapid heat exchange through direct contact, reducing cooling time and electrical input. Energy benchmarking reveals that water immersion systems can save up to 30-50% in energy use per unit of produce, making them more sustainable and cost-effective for post-harvest temperature management.

Cross-contamination mitigation

Water immersion cooling for berries increases the risk of cross-contamination due to shared water that can harbor pathogens, whereas air blast cooling minimizes microbial transfer by using cold air circulation without direct contact. Air blast cooling is preferred in post-harvest technology for maintaining berry safety and extending shelf life through reduced contamination.

Chilling injury threshold

Water immersion cooling rapidly lowers berry temperature below the chilling injury threshold of 0 to 2degC, reducing metabolic activity and extending shelf life without causing surface dehydration. Air blast cooling, while gentler, often struggles to uniformly maintain temperatures above this threshold, increasing the risk of chilling injury and uneven quality degradation in sensitive berry varieties.

Berry microcrack permeability

Water immersion cooling enhances berry microcrack permeability by facilitating rapid water ingress, which can increase the risk of microbial contamination and quality degradation. In contrast, air blast cooling minimizes microcrack permeability by using cold, dry air to reduce surface moisture, thereby preserving berry structural integrity and extending shelf life.

Water immersion cooling vs air blast cooling for berries Infographic

agridif.com

agridif.com